Idle Air Control Valve or IAC Valve Symptoms & Costs To Replace

The Idle Air Control Valve (IAC) is typically used in fuel injected car engines to control the engines idling speed. RPM is also known as rotation speed.

Vehicles that use a carburetor also use a device that is similar. It is an ISC or Idle Speed Control actuator. Both devices keep the engine revolving at a constant speed and prevent it from stalling.

What does the Air Control Valve Do?

The IAC mainly controls the amount of air that is taken into the engine for combustion while the engine is running.

Overall the cars computer system is monitoring inputs from a variety of sensors which provides information on engine speed, airflow, fuel combustion, and much more.

Plus, the engine computer will actuate a control motor on the IAC that will allow more or less air into the engine which in turn will control the engine speed.

The engine computer maintains the engine speed at a minimum level that is pre-set. If it were not pre-set and maintained, the car would stall the moment the driver took the foot off the gas pedal.

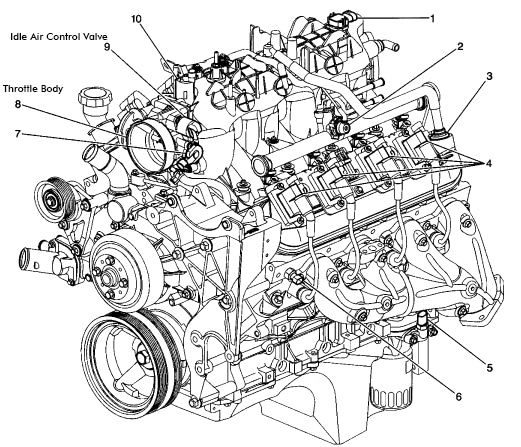

Where is the Idle Air Control Located?

The actual location of the idle air control valve will depend on the model, year, and make of your vehicle. Check your car’s manual for more information on the actual location. Usually, the valve is located on the air intake manifold, or throttle body.

Top 6 Bad Idle Air Control Valve Symptoms

The idle air control valve is designed to last the life of the vehicle; however, it can fail from time to time for a variety of reasons.

Usually, the IAC malfunctions because dirt gets into the system through a faulty or dirty air filter, and the actuator cannot be controlled by the car’s computer system.

Occasionally the IAC will fail entirely and need to be replaced. The engine will idle roughly in this situation.

Completely Damage Valve

If the IAC continues to not work properly after a thorough cleaning, it is likely the servo motor that has failed. The IAC will need to be replaced if the servo motor fails to operate.

If you begin to experience the engine idling poorly, stalling or the engine shuts down altogether, have a mechanic diagnose the problem.

A failed IAC may also trigger the check engine light and provide a code for the mechanic to verify. Of course, drivers should remember that the check engine light can be actuated for many different reasons when the engine is running.

Vehicles Engine Stall

A completely failed IAC will not allow air to enter the engine and it will stall as soon as it starts. Drivers may notice a gradual failure of the cars idle control valve.

The idle speed that is not consistent and regular is one indicator. Also, the check engine light might also turn on. The actuator valve could be stuck and will not adjust in response to signals from the engine’s computer.

While the engine may not stall, it will not run smoothly and may not deliver the appropriate level of power when needed. Have the IAC checked before the vehicle’s engine stalls?

Irregular Speed of the Engine

The IAC is controlled by the car’s engine computer to deliver a smoothly idling engine.

If the actuator valve is beginning to fail or if dirt or oil somehow gets into the idle air control valve, the computer will attempt to rectify the situation by increasing air intake or decreasing air intake as needed.

The computer will in most cases turn on the check engine warning light, and the engine will not run smoothly.

Car owners will hear the engine RPM (revolutions per minute) slowing and increasing as the system tries to compensate. Your engine may even stall as the IAC fails or if dirt builds up in the system.

Check Engine Warning Light

The check engine light can be turned on for several reasons. A solid light indicates that the driver should have a mechanic inspect the car soon.

A flashing light suggests something more serious is going on and the driver should pull off the road and turn the engine off to avoid potential damage to the engine.

The engine control module or computer turns on the check engine warning light when it receives a message that the IAC is not operating properly. An error code is generated and stored in the ECM for later retrieval by a mechanic.

The Cars Idle Isn’t Smooth

The IAC controls the air intake to the car’s engine. Irregular air intake can cause the engine to revolve at too high a speed and too low a speed at times.

The engine may even stall when the car comes to a stop at a stoplight or stop sign. In some situations, in heavy traffic, for example, this could place the driver in a dangerous position.

The Engine Idle Because of a Vacuum Leak

Your engine may not idle appropriately because of a vacuum leak. The IAC is working correctly but cannot compensate for the leakage.

The actuator may be fully extended (closed) because the ECM is trying to lower the engines idle speed. Your mechanic will check the codes and the position of the actuator to confirm this problem.

What Does the P0505 Code Mean?

The P0505 code is generated and saved by the ECM or engine control module when the idler air control module fails to operate, or the engine idles roughly.

The ECM saves the code for later review by a mechanic. The engine light may be on; the engine is idling at higher or lower speeds than designed, the engine may be idling in a rough manner or even stall.

How to Diagnose a P0505 Code?

Start by scanning the code stored in the ECM. Check the engine idle speed to check a car that idles within specifications.

Check for vacuum leaks, and for carbon and dirt around the IAC valve inlet.

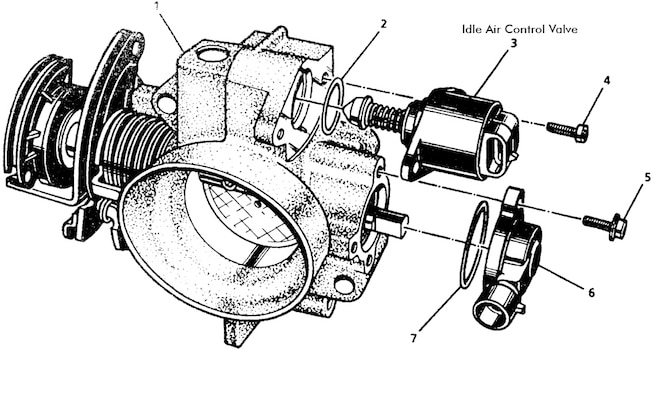

Remove the IAC and clean as needed. Look for blockages in any of the channels and verify if the actuator is operating.

Can you Drive with a Bad Idle Air Control Valve?

Most times, you may be able to drive your vehicle with a bad idle air control valve. The engine may be idling roughly, or it may idle at too high an RPM. However, as the problem progresses, the car may stall at the most inopportune times.

Stalling at a stop sign or traffic signal light with lots of traffic around will create a potentially dangerous and stressful situation. Stalling on the highway in stop and go traffic can be much worse.

Your car shuts down, trapped in the middle lane, with no way to start your car and move to the side of the road, could be quite dangerous.

The car also loses braking power since the master cylinder has lost the power assist function. Even, powered steering systems also lose power, making it difficult to steer the car.

How Do you Know If your IAC Valve is Bad?

There are several indicators for diagnosing a bad IAC valve. Your car’s engine has an irregular idle speed, which is the most common symptom. The check engine light might turn on, and the engine may stall.

Engine stalling is a more serious indicator. Your car’s engine may not idle at all. It also may be challenging to start and stalls immediately.

Checking the ECM error codes will indicate the appropriate code, P0505 has activated and was stored by the engine control module. Your local mechanic will use a code reader to access the codes stored by the ECM.

Replacement Cost for Idle Air Control IAC Valves?

The replacement cost for the IAC module includes diagnosis and replacement of the unit. Depending on the make and model of your vehicle, the repair shop used, the average cost appears to be near $350. However, some repairs could be as much as $500 in total value.

Can a bad Idle Air Control Valve Affect Gas Mileage?

Gas mileage efficiency can be impacted. High car idle speed will utilize more gasoline, especially when you are sitting in traffic. The valve will be fully closed at highway speeds and should not affect gas mileage.

Stalling and rough idling can also draw more gasoline as well as produce more unburnt fuel to be recirculated by the EGR valve. You could end up with empty fuel tanks or gas tanks prematurely.

How to Reset My Idle Control Valve?

Consumers cannot reset the valve physically. The process for resetting the valve goes as follows:

- Depress the gas pedal slightly

- Start the engine and also let it run for 5 seconds

- Make sure you turn the ignition switch off for 10 seconds

- Start the engine and check for idle speeds within manufacturers limits.

Can a Bad IAC Valve Cause Overheating?

In most cases, a bad IAC valve will not cause overheating. Many new car models have cooling fans that are electric and will run whenever the ignition is on.

Even in cars with the older style fan belts that are run off the engine, it is unlikely. Temperature sensors will trigger the check engine light to be illuminated.

What is an Idle Air Sensor Control?

The idle air sensor control device manages the amount of air entering the engine while the engine is idling. The engine control module senses the idle speed and either open the actuator or closes it to let more or less air into the engine.

How to Clean the Idle Air Sensor Control?

You can follow this list of steps to clean the idle air sensor control:

- Disconnect the car battery cable

- Locate the IAC and remove the screws that hold it in place. Draw a diagram of the connections for later reference. (Use a test light to help find the IAC)

- Disconnect the electrical connections

- Remove all hoses and plugs

- Remove the gasket, ensure that you have the correct replacement gasket

- Use carbon cleaner and a cloth to remove all dirt from the IAC

- Reconnect the hoses and attach the IAC

- Reconnect the battery cable and proceed to start the engine.

Video on How to Check an Idle Air Valve

Other Things to Check for When your Car has Poor Idling

In addition to the IAC malfunctioning, the following could also cause your engine to idle poorly:

- A vacuum leak in one of the hoses

- A bad spark plug or spark plug cable or ignition coil

- A fuel injector not working properly

Engine control unit

The engine control unit or engine control module receives information from several sensors on the engine. This information is used to manage the air intake and gasoline intake to ensure optimal engine performance at idle speeds and while driving.

Oxygen sensors

Oxygen sensors measure the amount of oxygen at the tailpipe, feeding this information to the engine control module. The ECM makes adjustments to air intake and exhaust gas re-circulation to ensure the engine is operating within specifications from the manufacturer while idling and driving speeds.

Crankshaft position sensor

The crankshaft position sensor monitors the position of the crankshaft and the rotational speed of the shaft. The ECM uses all this information to control the fuel injection system and the ignition timing.

Any time a sensor malfunctions, it causes the ECM to attempt to compensate. However, it often causes a loss of power or poor idling characteristics.

MAP sensor

The manifold absolute pressure sensor provides instant pressure readings to the ECM. The information is used to calculate air density, air flow, and the optimum amount of fuel to deliver to the engine for maximum performance at all speeds and rpm.

Intake manifold

The intake manifold merges the air fuel mixture and delivers the gases to the engine for combustion.

It is crucial that the air fuel mixture is distributed uniformly to each cylinder to ensure optimum performance. Sensors relay information to the ECM, which in turn controls the air fuel mixture in the fuel system.

Spark plugs

Spark plugs provide the spark to ignite the fuel air mixture in the cylinder. A bad spark plug can cause poor acceleration, engine misfires, poor fuel economy, or even difficulty in starting the engine.

The check engine light may also be illuminated if there is a bad spark plug due to sensors picking up irregularities in the exhaust gas emissions.

Throttle position sensor

The throttle position sensor monitors the throttle and the air intake. It is attached to the throttle housing. A faulty sensor can cause rough idle conditions, stalling, poor acceleration, low power at highways speeds, increased fuel consumption, and even misfiring. Have a mechanic check the error codes in the ECM and also the sensor.

What’s the Best Scan Tool or Code Scanners to Check an Idle Air Valve?

Scan tools or code scanners can be used to check the error codes saved by the ECM. Usually, the check engine light has been turned on by an event such as a faulty sensor or readings that are outside the manufactures specifications. Use the scanner to read the code which will point to the unit or sensor that is reporting a malfunction.

Before purchasing a code scanner, consumers should verify that it will connect to and read the error codes from your car’s ECM unit. Most are very straight forward to use. Proper scan tools can alert you if you have a faulty exhaust manifold, bad O2 sensor, and you turn off the check engine light.

Conditions To Evaluate

The IAC or Idle Air Control valve controls the amount of air entering the engine while the car is idling. The Engine Control Module actuates a servo motor on the IAC to regulate the air needed to maintain proper idle speed.

A faulty IAC unit can cause the engine to idle at higher or low idle speed or even cause the engine to stall. In some cases, the engine may not even start.

Other conditions can cause similar symptoms. Faulty sensors delivering poor readings to the ECM, vacuum leaks in one of the hoses connected to the IAC, faulty sparkplugs or glow plug wires can cause poor idle characteristics and low power conditions.

What Happens When the Idle Air Control Valve Goes Bad?

The idle air control valve IAC or P0505 code triggers the check engine warning light as an alert. Other symptoms can be a faulty exhaust manifold gasket and throttle bodies. Have a mechanic check the ECM error codes and take appropriate action to make repairs.

If you have poor gas mileage performance, then your mechanic should also check the fuel injectors, intake manifold, fuel pump, and cylinder head.

The car battery, wiper blades, and oil filter should be something that you can change yourself. But when it comes to more complicated like the IAC valve failure, you should rely on a professional to get it done right.

Other signs of a bad IAC valve are having trouble to start the car, and cylinder head gets clogged up with carbon buildup, a dirty or clogged air filter, and a sticky gas pedal. These problems will cause high idle RPMs making your car less gas efficient by pulling more gas from the fuel tanks.

Conclusion

Replacing the IAC valve or idle air control actuator can increase your idle performance when you get your vehicle engine running. The control air valve allows bypassing the throttle to allow air into the engine.

You should check the IAC valve when you notice that your cars RMPs are too high when you start the engine. A faulty idle valve can lead to more significant problems an sometimes is considered one of the common reason why your car will not start.

Other things you can do to improve the performance of your car is to clean your engine bay, steering wheels, fuel tanks, and exhaust manifold gasket.

Also, have your mechanic check the air filter and the fuel injectors. Making all these improvements can lead to a better speed of the engine and better performance when it comes to gas mileage.

Last Updated on: November 3, 2022