How to Choose Coilover Spring Rate? 5 Steps to Succeed

Before we get into the details of choosing the coilover spring rate, it is useful to take a few moments to understand the functions of the spring, the shocks, what a coilover is, and the support they provide to the suspension. The job of a spring on a car is to support the total weight of the vehicle.

How to choose coilover spring rate? Every car has a different weight depending on the vehicle’s design, the options added to the car, and the number of passengers the vehicle is designed to carry. Soft springs improve ride quality, while a higher spring rate introduces a harsher ride and compromises ride quality.

Softer spring rates ensure that the tires maintain contact with the road surface and hence provide better control. Adding shocks controls the speed of compression and depression of the springs. Sway bars limit body roll. There are calculators available to help determine the perfect spring rates when using coilovers.

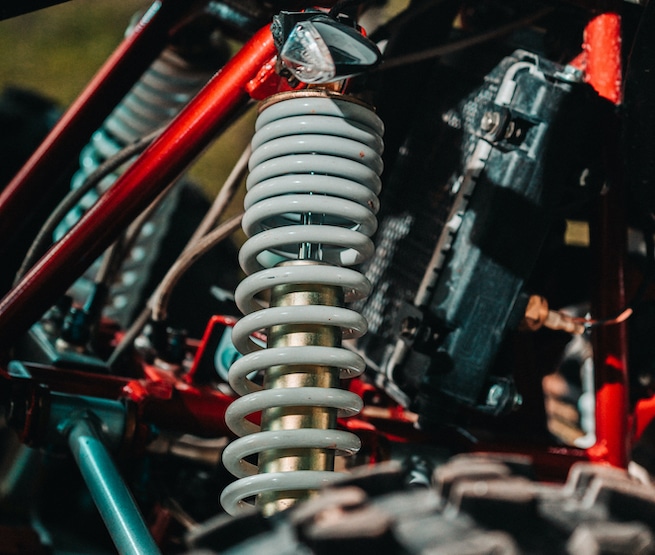

Coilovers are springs enclosing the shocks specifically designed for your car to provide the correct ride preload. Selecting the correct spring rate ensures that the shocks operate in their sweet zone providing the dampening appropriate for the weight of the car and the desired performance of the driver.

Choosing incorrect springs can lead to bad suspension feeding data. Anytime shocks are taken outside their ideal range, they will not perform well. It is up to the springs to deliver the recommended spring rate to keep the shocks in the zone where they deliver their maximum performance.

Select the right springs for the type of driving you are planning to do – street, drag racing, hot rod, race cars, and more. Solid axle rear suspension can utilize either coil springs or leaf springs. Many trucks utilize leaf springs.

Finding the Correct Spring Rates

The objective is to limit shock travel to 3 to 4 inches to ensure they remain in the sweet spot and deliver their maximum performance. The ride height of the chassis sitting on the springs should ensure that the shocks are within this 3 to a 4-inch window.

In addition, to gain the desired height, there may be a need to install an upper spring on top of the lower spring with a bushing in between. Wheel travel will translate into longer measurements since the wheel is further from the focal point. Before you select the spring rate, determine the type of driving that you typically will be doing or the desired quality of performance.

For example, drag cars require more rebound and less compression, and streetcars are the opposite. A street car encounters unexpected road hazards such as bumps and potholes. They require 60% of the shocks travel for compression and 40% for the rebound.

Cars running on a smooth track require less compression and rebound. They can benefit from a 50/50 split. As road surfaces change, the total travel percentages may need to be changed to reflect the hard surface to avoid the shocks from bottoming or topping out.

Selecting the correct spring rate for your car requires the weight of the car, the type of driving you will be doing, and dividing the weight between the front end and the rear end of the car. This is typically 55% for the front and 45% for the back of the car.

#1 Find the UnSprung and Sprung Weight

The unsprung weight is the weight of the vehicle not supported by the springs. This includes the brakes, rotors, tires and wheels, wheel bearings, control arm, and the steering knuckle.

The rear unsprung corner weight is usually around 150 to 175 pounds, while the front unsprung weight is around 100 to 125 pounds. The rear weight will also vary for the sprung rate measurements from the front sprung rate.

For the sprung weight, find the specific vehicle weight for your vehicle. While the best approach is to measure the weight of the vehicle, front and back, many people will assume a 50-50 split and divide by two to get the corner weight or sprung weight. Depending on the vehicle, it may be more accurate to assume a 60-40 split front to rear in your calculations.

#2 Measure The Control Arm Pivot Point Distance

The “motion ratio” is the advantage the wheel has in mechanical terms on the spring in compressing it. The motion ratio can be calculated by making two measurements as follows:

A) Measure the length from the control arm pivot point to the centerline of the ball joint.

B) Then, measure the distance from the control arm pivot point to a point under the center of the coilover assembly of the spring.

Once you have these measurements, divide B by A to obtain the motion ratio.

#3 Determine The Coil Spring Angle Needed

In most vehicles, the coil spring angle will be between 75 to 90 degrees. Measure the angle between the center of the spring or coilover assembly and the control arm. Many conventional springs have a coil spring angle of 90 degrees. This is the measurement used to determine the force angle of spring force that is applied to the control arm.

If you cannot make this measurement assume 75 to 90 degrees. Many people will select a measurement somewhere in the middle of these two bookends.

#4 Choose The Spring Length and Shock Stroke

It is important to find the right balance between spring length and shock stroke. Linear springs will start compressing at a linear rate as weight is added, i.e., compresses one inch /xxx pounds. The spring length should be selected based on the amount of compression and weight of your car.

Online tools are available to provide assistance based on ride height, size of the spring, and the amount of stroke for your shock. Drivers will want the spring to be long enough to handle the travel length of the shock and be soft enough to start the compression without bottoming out.

#5 Calculate The Final Spring Rates

Spring rate is how much the spring compresses as weight is added to the springs. If a 12-inch spring compresses four inches when 600 pounds are added, the spring weight is 150 pounds per inch. Knowing the uncompressed free length of the spring and the corner weight of the vehicle, you can calculate the perfect spring rate.

A stiff spring will not compress and provide a rougher ride, while a soft spring provides a smoother ride. Aim for springs with a spring rate that compliments the shock being used and keeps the shock travel rate within the sweet spot.

What is a good spring rate for coilovers?

Everything you do to your car in terms of modifications that add or subtract weight, including the number of passengers carried, affects the spring rate and the performance of the coilover springs.

The job of the spring is to sustain the weight of the car. Higher spring rates reduce body roll but deliver a harsher ride. While a softer spring rate will improve ride quality, the tires can follow the road surface better and avoid the tires losing their grip on the track.

Shocks have a limited range of motion. The spring rate needs to make sure that the shocks operate in this range to avoid bottoming and topping out as the car corners or hits rough patches in the road.

The springs should ensure that the shocks are always operating in their sweet spot. In most cases, the travel space for shocks should be no more than three to four inches.

If you travel on predominantly smooth roads, the springs should position the shocks to travel 50% in either direction. Street cars that encounter many different road conditions should be positioned for the shocks to have 60% allowed for compression to deliver a smoother ride and allow for road hazards.

How do I know what size coil spring I need?

Selecting the size of coil spring needed for your vehicle is based on the amount of weight that must be supported by the spring and the ride height you want to achieve. The weigh that must be used is the sprung weight and not the unsprung weight.

For example, if the corner weight that must be supported is 1000 pounds and you have spring rates of 200, the spring will produce five inches of compression under the weigh of 1000 pounds.

With a compression of 5 inches, this should place the spring in the sweet spot of the shock and allow the shock to compress 50% in either direction unless you are driving your car on the street, in which case you would aim for a 60-40 split.

If you plan to customize your vehicle, you will need to measure the corner weight of your vehicle and determine what spring will be needed to support the weight of the car to provide the appropriate amount of travel and ride height.

Adjust the ride height by varying the coilover spring rate installed. For example, for 1000 pounds, using 150-pound spring rates would cause the ride height to change substantially to more than 6 inches.

MaXpeedingRods offers various of coilovers with regular value spring rates to meet the requirements of most car users, and based on its 16 years of suspension manufacturing ability, MaXpeedingRods are also incredibly flexible in providing customized service on spring rates.

[su_shadow style=”simple”] [su_panel shadow=”none”]MaXpeedingRods Coilover Kits

- 24 levels of damping adjustment for good handling

- Able to lower the ride height by 1”-3”

- High tensile strength performance spring

- Make custom spring rates to your exact specifications

How to calculate your effective Coilover load?

The effective coilover load is the effective sprung corner weight of the vehicle. You will need several pieces of information:

- The free height of your coilover springs

- The compressed height of your coilover spring

- The spring rate of the springs installed on your vehicle

With this information, you can quickly calculate the load being placed on the coilover springs. Subtract the compressed height from the free height to calculate how much the spring has compressed with the weight of the car on it. Let’s assume four inches.

The spring rate is how many pounds it takes to compress the springs one inch. We are assuming a linear compression. If the spring rate is 200 pounds, then it takes 200 pounds to compress one inch, 400 pounds to compress 2 inches, and so on.

Now that we know the spring rate and how much the spring has compressed in inches, the effective load on the coilover is four inches’ times the spring rate of 200 or 800 pounds. This is the effective corner load of the vehicle in its current state. Adding passengers, cargo, etc., will increase the effective coilover load.

Coilover Spring Rate for Drag Racing vs Daily Driving

The type of driving during daily driving on the street is much different than drag racing. Street driving involves many road hazards and uneven road surfaces, while drag racing involves a much smoother surface and high speeds. Spring rate is the number of pounds required to compress the springs one inch.

Most springs are linear, and therefore as weight is increased, the spring compresses linearly. If you have a 225-pound spring rate, it means the spring will compress one inch when it supports a 225-pound weight.

For most street-driven cars, it is expected that the spring will compress 25% to 30 percent when the weight of the vehicle is added, while drag cars typically compress the spring by thirty to thirty-five percent.

You want to have sufficient available spring or enough travel to support the ride height desired for the vehicle. The spring rate for the drag car should have sufficient stored energy to handle the launch of the vehicle.

Selecting linear or progressive rate springs provides another dimension to consider. Essentially progressive spring rates increase as the spring is compressed. The opinions expressed by many drivers appear to handle both linear and progressive, and it comes down to personal choice regarding which one you select.

Coilover Shocks Last Tips & Tricks

Coilovers provide improved handling and ride comfort. However, they can degrade over time depending on the type of surface your car is exposed to. There are several tips & tricks to ensuring they last the lifetime of the car.

While installing, use proper tools to avoid damage to the internal housing of the coilover.

Replace older bolts when installing new coilovers. Existing bolts may be oxidized and corroded.

Set the ride height accurately and take accurate measurements.

If your car is not aligned, get it aligned properly; otherwise, tire wear, traction, handling may suffer even with new coilovers installed.

Keep them clean – remove mud and grease from the coilovers to prolong their efficiency.

Avoid rusting; apply anti-seize lubricant – to keep the coils from rusting along with the caps to avoid rusting. Apply anti-seize every year before winter to protect them from salt and dirt.

Check screws and bolts regularly – make sure they are tight and have not come loose during rough road trips and conditions.

Use coilover covers – to protect the coilovers from dirt, road salt, and other contaminants. Helps to keep them clean.

Stay away from potholes and bumps – may push the coilover to top out or bottom out, which can lead to degrading over time.

Maintain rubber bushings and replace if needed – check regularly and replace as needed. Metal on metal can lead to premature wear and tear.

The shock angle at which the coilover unit is installed has a significant influence on the spring rate requirement. Shoot for more preload and a longer arc for the rearend housing.

Last Updated on: March 16, 2025