Best Plasma Cutter For The Money [Top Picks & Guide] 2023

The world is made up matter. Plasma is among the four fundamental elements of matter. The other three states of matter are solid, liquid and gas, with plasma being the fourth. Unlike the other three states, plasma has very different properties.

Due to its unique properties, it is used for many things, including cutting through materials that can conduct electricity. This is where finding the best plasma cutter for the money comes into play. Quality plasma Cutters have revolutionized how metal and electrically compatible objects are cut.

Anyone who has not yet embraced this technology is missing out on an good opportunity to save costs, time, and energy. In the market, there are several plasma cutters, and go over our plasma cutter reviews to become more aware before making the final purchase.

Key Features

The Hypertherm Powermax45 is our first top cutting equipment for its portability. Its smart sensor makes this unit the top cutters for the money, and it allows you save lots of time by providing a superior quality of cuts. Additionally, it is super light weight and small in size.

Also, you can achieve fast cuts with a patented tech that is 1.5 times greater than other conventional systems. Do you plan to make cuts of huge objects that occupy a larger space? This is the one to go for. It is sufficiently large and also well able to manage such much larger loads.

Besides it can be paired and it work well with a table that is specifically designed to work efficiently. Why not get hold of it and deploy it for that role? We consider this product one of the best plasma cutters available on the market today.

Key Features

If all you want is to impact metals that are heavily rusted or greasy, you have no better friend and companion. It basically gives you the leeway to start the arc without necessarily having the wires touch the workpiece. A convenient automatic dual-voltage technology also exists as part and parcel of this machine.

It sees to it that you run the various voltages with limited hassles in your part. By its stature and construction, it pierces through rusty, painted, and rough surfaces. Then again it suffers minimal slag in the course of tackling the various chores.

Key Features

The Lotos LTP5000D model is the latest Lotos tech for plasma cutters. It is a 50Amp Non-touch Pilot Arc device with a dual voltage of 110 and 220. Its manufacturer describes it as a 1/2 inch clean tool.

According to customer feedback, the Lotos works best on the latter voltage 220V but also works quite effectively at 110V. For this product to be used well, a person will need two items: an air hose which has a female connector. With a female connector, one can easily connect and disconnect the air inlet.

The other essential element is the air compressor that comes with this high quality plasma cutter. Planning to cut across numerous surfaces? You have to pick and use a similarly device of this kind. Lotos plasma cutter is one of the best cutter for the money.

Key Features

This SungoldPower is the one to look up to if you do happen to change your locations every now and then. It is pretty portable and hence convenient to deploy remotely. Its flagship trait is the IGBT tech that makes it far more stable and superior to the ordinary machines of its nature.

It uses of the most advanced inverters to be able to discharge the stream of plasma that is subsequently used for multiple tasks. Moreover, it is also elaborated by the use of impact-resistant materials. That also makes it last longer not to mention guaranteeing elongated length of service.

Key Features

The Hypertherm PowerMax30 XP has a casing and is an American edition with a two in one version. It can cut thicker metallic surfaces as well as delicate materials which need exceptional precision. These portable plasma cutters are well packaged and the weight is easy to handle.

Additionally, these Hypertherm PowerMax 30 cutters come with consumables such as plugs that could be used for both the 120V and the 240V circuits. Also, it comes with shaded glass, a carrier case, and a shield mask and even gloves. Could it be that you want to cut for a prolonged duration of time?

Set your eyes on this unit as it is the one that is optimized for the matters of maximum comfort. Moreover, it is also manufactured by the use of impact-resistant materials. That also makes it last longer not to mention guaranteeing elongated length of service. You can find the pros and cons of the PowerMax30 XP below:

Key Features

The Ramsond Cut 50dx is our fourth top pick for its impressive 60 percent duty cycle performance. The sever cuts production is superb with a maximum of a 1-inch max cutting thickness of steel. With its integrated pressure gauge, this Ramsond machine is by far the best plasma cutter for the price.

If you happen to change locations every now and then, you want a model that can guarantee your performance regardless of where exactly you may be at any given time. By virtue of allowing for dual voltage performance, no other cutter comes even close to this. Read the pros and cons to understand why you should consider making use of this one for your on-the-go applications.

Key Features

The Versa cut60 plasma is a sharp cutter. It can easily slice materials that are 7 or even 9 inches thick. Not only does it cut through the thick metals, but it also cuts through any surface and has a neat cut to it.

Its built-in pilot arc allows an operator to have stability and precision when you cut. It happens to have an in-built moisture separator which would enable only clean air to pass through the plasma torch. Its flagship trait is the torch cable that measures a whopping 20 feet.

For multiple applications, we vouch for no other cutter than this one. It is extremely powerful and truly reliable enough to be able to pierce through extremely thin materials. You use this to channel the flow of the plasma to the exact spot where you need it to be.

Key Features

The 500564 Airforce 12i is the way to go if one needs an affordable plasma cutter that works perfectly at home or in small welding environments. It works perfectly in harsh environments but is comfortable to use.

This unit is perfect to work at 104 degrees Fahrenheit temperatures, but keep in mind that it delivers low quality cuts for thick surfaces. Inverter technology also forms a vital part of this unit. It furnishes the powerful cutting capabilities that can pierce through the strongest steel.

Without a doubt this is a small plasma cutter that any mechanic add to their garage. Lacking in the strong muscles? Pick a portable plasma cutter that is easier to carry around like this one.

It comes ready assembled and ripe for use. Furthermore, it can work in touch environments with a 35% rated duty cycle at 104F degrees, but has an inbuilt coolant which enables a comfortable working environment.

Key Features

The Everlast PowerPlasma is not an affordable plasma cutter. It is a multipurpose Welder with dual voltage, i.e., 110V and 220V. Also, It is an fantastic tool for portable duties since it is a quality tool. It is also great at repairs that have to do with thick jobs.

Do you need a great cutter? Choose this powerful, stable, and durable cutting machine as it is better for constant usage. Thanks to the easy cut tech, it also pierces through the rusty or painted surfaces with absolute precision.

Look no further this is one of the best plasma cutters for your money. However, warranty may be limited to some countries. Perfect if you are looking for a low power consumption device. Also, It boasts of an easy starting as it makes use of the pilot arc to do so.

Key Features

The Hobart Airforce 27i has a cut width of 3/8 and 5/8 mild steel. It is not a cheap plasma cutter because of its wind tunnel tech that reduces the amount of debris and dust that is pulled into the unit. Also, we recommend the Airforce 27i for those who are looking to cut metal thickness between 1/4 and 3/9 inches.

Additionally, It comes with a built-in compressor and lightweight tech. Many materials of these kinds demand that you attach an external air compressor to be able to cut metals. Not so with this one. Instead, it has a built-in air compressor to do the job on its own. That maintains it compact and hence easier to carry around if and when the need to do so may arise.

Key Features

The Thermal Dynamics Cutmaster 60i has advanced gas optimizer technology to increase the consumables life. With maximum sever cuts performance of 16mm, the cutmaster is considered one of the most powerful among the competitors. Also, it comes with the SL60QD 1Torch for easy replacement. When it comes to a cutter that produces clean thin metal cuts, the Thermal Dynamic is the go tool.

Also, it comes with an amazing technology that protects the consumables lifespan. This might be the best one to consider leveraging. Looking to etch out some decorations as well? Choose to work with a budget plasma cutter that is similarly pretty agile and able to maneuver itself out and about easily. Its integral multi-handle design is what enables it to make those decorative marks with precision.

Key Features

The Airforce plasma metal cutter is an great fit for someone that is looking for both light and industrial use. The Hobart Airforce 40i can withstand sever cuts of 7/8 inches of steel, which is not bad for a portable cutter. It is considered a potent plasma cutter that can be transported with great portability.

Comes with one of the best trigger systems on the market. Also, it can perform well on both thin and thick materials. However, it only operates under 240 volts of power, and is not as light as other models. These high quality plasma cutters and tools are used among all top body shops because of the quality of cuts.

Who said you have to acquire larger and bulkier cutters for your powerful applications. Even one that is smaller and lighter of this kind may still be of help to you. Though small, this one is able to exude a whopping 40 amperes of power output. This output is sufficiently large to be able to yield everlasting impacts.

Key Features

The Miller electric company has created the most potent 40AMP portable cutter on the market with a cutting ability of 5/8 mild steel thickness. Also, the Miller Spectrum 625 cutter offers a dual voltage connection with incredible Auto-Line technology. Well known brand cutters that comes with outstanding LED indicators for better workflow. Can’t go wrong with the miller spectrum 625 X-treme plasma-cutter.

In order to cut through your metal carefully, you have to get a particular plasma cutter that is appropriately designed and suited wholly for metal cutting. With its metal cutting design, this item is a good one to pick and deploy for the job. Its dimensions and overall stature also combine to make its work awesome.

Key Features

This fantastic lightweight and portable plama cutter is perfect for any DIY home repairing or cutting job. Also, it is not recommended for beginners due to some installation complications that requires experience. If you are generally a do-it-yourselfer, this one is for you.

It is a machine that can be deployed and handled with ease. Then again it is devoid of those powerful and sophisticated parts and components that machines of its kind ordinarily possess. For this reason, it is overall simpler to make do with.

Additionally, If you are looking for a decent metal cutting ability with a significant percentage of savings, then consider the Amico CUT-50. It is on our top pick list for the versatility and we believe that this tool could be one of the best cutting system for the money.

Key Features

The AHP plasma cutter has a recent 2016 model called AlphaCut 60 60Amp plasma cutter. This cutter has a dual voltage of 11oV and 220V. It has a great pilot arc which enables a user to cut through objects like rusted metals, painted and even expanded metals precisely.

Extremely versatile machine that can be used both commercially and for personal DIY projects. Known to produce clean cuts for mid-sized thickness. Also, overall this equipment produces high quality cuts, and allows you to switch from 110v to 220v almost instantly with the power adapter.

Is your search for the right cutter mainly dictated or informed by commercial use? Look up to no other cutter than this one. It does have the blow-back start technology that makes this possible. Adding to this is the ability to exude a whopping 60 amperes of output that in turn generates massive professional cutting power for you. All these make for the cutting of bulky applications!

Top 15 Best Plasma Cutter Reviews

Rankings Name Price and More Details

Lotos LTP5000D 50AMP Pilot Arc Plasma Cutter Click Here

Hypertherm Powermax45 American Build Edition Click Here

Ramsond Cut 50dx Plasma Sytem Click Here

Thermal Dynamics Cutmaster Click Here

Hobart Airforce 40i Plasma Cutter Click Here

1. Hypertherm Powermax45 Plasma Cutter

2. PrimeWeld Cut50 Plasma Cutter

3. Lotos LT5000D Plasma Cutter

4. SungoldPower 50A Plasma Cutter

5. Hypertherm Powermax 30 XP Plasma Cutter

6. Ramsond Cut 50dx Plasma Cutter System

7. Eastwood Versa Plasma Cutter

8. Hobart Airforce 12ci Plasma Cutter

9. Everlast PowerPlasma Air Plasma Cutter

Adjustable Post Flow (power plasma only) controls

10. Hobart Airforce 27i With Built in Air Compressor Plasma Cutter

11. Thermal Dynamics Cutmaster Plasma Cutter

12. Hobart Airforce 40i Plasma Cutter

13. Miller Spectrum 625 X-treme Plasma Cutter

14. Amico Cut50 Plasma Cutter

15. AHP AlphaCut Plasma Cutter

Best Plasma Cutters Buying Guide

There are a variety of plasma cutters on the market with various features and excellent cutting capacity. Before you decide on which machine to purchase, verify the specifications and the reviews for each device.

Make a decision on which features and capabilities work best for your application and use. Take into account the price, power hookups, e.g., 120 or 240 Volt and amperage requirements, and how efficient they are in comparison to the consumables and cost of the consumables.

Some of the best plasma machines come with built-in air compressors to supply compressed air while others require external high capacity units. Also, these units can come equipped with dual voltage systems. Sometimes brick and mortar stores do not have the top plasma cutter features. For example, a Ramsond Cut 50dx plasma cutter can be purchased for less than five hundred dollars.

What is a Plasma Cutter?

A plasma cutter is an equipment generally used for the cutting of electrical conductive objects like aluminum, copper, or steel. Various industries use a plasma cutter for their activities. Examples of places that use plasma cutters are welding shops, industries, automotive industries, and even in metal scrapping and salvaging industries.

Plasma cutting over the years has become an excellent way of cutting any form of electrically conductive metal. It is an exact method, it is faster than the other methods, and it is also cheaper than other methods. This research was conducted and reported by the body called Computer Numeric Control (CNC).

How a Plasma Cutter Works?

A plasma cutters is found to be useful in cutting sheet metal in angled or curved shapes. Hand-held torches can cut up to 38 mm or 1.5 inches’ thick steel plate. These cutter machines controlled torches controlled by computers can cut through steel that is up to six inches thick.

A grounding clamp is attached to the metal to be cut to complete an electrical circuit. The plasma cutter generates super-heated electrically ionized gas, which completes the electrical circuit back through the grounding clamp. Some form of compressed air is blown through a focused nozzle at high speed towards the working artefact. It can be oxygen, air, or inert gas.

An electrical arc forms within the chemical, creating an electrically conductive channel of plasma which delivers sufficient heat to melt the metal being cut. The compressed air blows the metal surface away in effect separating the metal or cutting through the work-piece.

What is plasma cutting?

Plasma cutting describes a process of cutting through materials that conduct electricity using an accelerated jet of hot gases or plasma. Steel, aluminum, and copper are the typical materials cut using this process. However, anything that conducts electricity can, in theory, be cut with a plasma cutter.

The process is used in hobby shops up to and including large scale industrial manufacturing and repair shops. Due to their high speed and precision, a plasma cutter is used in fabrication shops, auto repair, and even salvage operations.

How to determine the amount of power that you need?

Just like a truck, the more power you have, the faster you can go with a giant load. Two plasma cutters with the same number of amps, but different voltages deliver much different power levels. Amps times volts gives you the number of kilowatts it provides.

A 120-volt system with the same current as a 240-volt system delivers less power. Slower cutting in terms of inches per minute and smaller thickness may be an issue depending on if you are a hobbyist or a repair shop, for example.

What kind of metals can a plasma system cut?

Typically, plasma cutters can cut through steel, mild steel, stainless steel, brass, copper, and aluminum. The power of the best plasma cutters also determines how fast it can cut through the material and what is the max cut of the material. These systems are known for its high precision and are popular with fabrication shops and industrial construction projects.

Things to Check Before Getting a Plasma Cutter

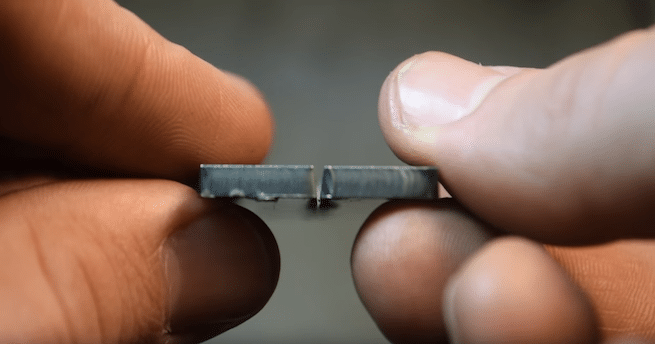

Plasma cutters are practical and efficient steel cutters. However, like most tools, they need to be handled with care, taking safety precautions seriously to prevent accidents. A adequately maintained cutter can also provide accurate, clean cuts without the need to make corrective cuts later on. Factors such as air quality, the cutting thickness, voltage levels, power supplies, and proper grounding are essential. Consumables should also be reviewed and replaced before they cause poor results.

1. Air quality

The process develops gases and noxious fumes that can be harmful to humans. Always work in a well-ventilated area or use filtration systems to remove particulate and noxious gases.

2. Metal thickness

Verify the thickness of the metal across the cutting area and also the capacity of your plasma cutter. Best results can be attained with a consistent thickness of metal and appropriate power for the thickness under consideration.

3. Input voltage

The input voltage and the amperage determine the overall power level in addition to the automotive cutting capacity in terms of thickness and speed of cut. Always confirm you have the right machine for the metal you are cutting.

4. Power source

The power source must have the voltage and amperage capability to power the plasma cutter. A 25-amp fuse on a 120 volt supply is not sufficient for a 40 amp – 240-volt plasma cutter.

5. Air pressure regulator

The air pressure regulator controls the pressure of the air injected into the system for great cutting. Check with your manufacturers manual for the optimum setting for your plasma cutter. They tend to vary between machines.

6. Ground

Electrocution is one of the most significant risks to users of plasma cutters. Proper grounding of the item to be cut, wearing rubber gloves and welding gloves, using a rubber mat to stand on and ensuring there is no moisture present is essential.

What are plasma cutter consumables?

Consumables in a plasma cutting machine are the materials that are slowly consumed when the device is being operated. If any of them are beginning to be worn down or begin malfunctioning, the cutting process becomes slower, and the actual cut can start to become more extensive. You may not even be able to cut through the metal surface at all at some point. The main parts are covered in the next section.

What are the main consumable parts?

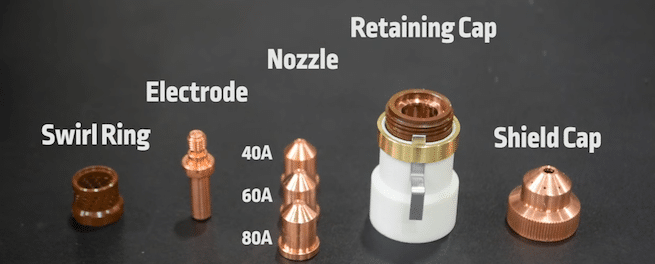

There are five different components to the consumable parts of a cutting machine – the shields, cap, the nozzle, the electrode, and the swirl ring.

- Swirl Ring: The swirl ring causes the more cooling gas to swirl on the outside to cool the nozzle. The air swirls around the electrode, around the arc, down the nozzle and out through the Torch.

- Electrode: The electrode is a slender piece of copper or silver and may contain hafnium or tungsten. The electrode carries the electrical current from the Torch to the plate.

- Nozzle: The nozzle focuses the plasma arc. Wide nozzles are used for gouging, while narrow nozzles are used for more delicate work for detailed shaping and cutting.

- Plasma Cutter Retaining Cap: The retaining cap in a plasma cutter is to cover and secure the other consumables together in position for efficient cutting.

- Shield Cap: The shield protects the consumables from a bad metal surface associated with the cutting process, therefore extending their life cycle.

How to improve consumables life?

Consumable life cycles depend on cutting capacity, distance held from the item being cut and whether the right consumables are being used for the correct type of cut. Slow cutting means higher temps which can use up the consumables more quickly. Worn consumables can reduce the life cycle more quickly.

How to protect yourself while using plasma cutters?

Plasma cutting machines use high voltage and high current electricity to cut thick metallic material. Improper grounding presents an electrocution risk. Sparks can ignite clothing and flammable liquids. The high-intensity light can hurt your eyes as well. Every user should use protective eyewear, headgear, footgear, and protective clothing. The work area should be ventilated and free of flammable liquids.

Welding Helmet

You should use protective eyewear and also face shields or helmets to safeguard the face from molten metal, which can severely burn your skin.

Flame Resistant Apron

Flame resistant aprons and unique clothing should be worn to safeguard your body and clothing from burns from hot metal. Leather, heavy wool or heavy denim seems to work well.

Leather Welding Boot

Hot metal can quickly burn through regular shoes. You should use a heavy leather high topped boots to cover their feet and ankles from flying metals.

Welding Gloves

Your hands are probably the closest appendage to the actual cutting process. They are exposed to hot metal. Utilize heavy gloves for extra protection.

Extra Welding Jacket

Continuous high power plasma cutting generates a great deal of heat, and molten metal. Many operators put on extra welding jackets to cover there clothing and bodies from burns.

Welding Carts

If you are not going to be using the plasma machine on a consistent base, then buying a welding cart can help you save money. There are a few welding carts that can help you safely keep your machine after purchase, and it can also help you keep your garage clean.

Plasma Cutting Duty Cycles Explained

An important consideration when purchasing a plasma cutter is the duty cycle. A machine with a 30% duty cycle means it can be used for three minutes out of every 10 minutes. A machine with a 50% duty cycle means you can use it for 5 minutes out of every ten minutes without damaging the device or its components.

The duty cycle is based on standards such as power supply, cutting at the maximum current level and the components inside reaching the maximum operating temp. Most plasma cutters come with sensors that can shut down the cutter when these standards are met. A cooling system may extend the duty cycle.

How does ambient air temperature affect the duty cycle?

Duty cycle standards are based on standard temps set by the manufacturer. Some plasma cutters use 70 degrees Fahrenheit. If your operating ambient temp is lower, internal components can take longer to reach their duty cycle levels. Similarly, plasma cutters located at higher ambient temperatures can lower the time the machine can be used.

What happens if you exceed the duty cycle in a system?

In most cases, nothing, because the plasma machine’s internal sensors can report overheating and automatically shut the machine off. If for some reason the sensors are bypassed, it can continue working for a short while and then overheat and possibly catch fire.

Advantages of Using a Plasma Cutter

Plasma cutting machines have several advantages over those or regular acetylene torches. Faster cutting, wide cutting capability, can cut all electrically conductive material or metal, works well-cutting sheet materials, excellent cutting performance on small and medium thickness steel, relatively low consumable expense, and a capability of cutting high-quality edges.

They are very portable as long as there is a compatible electrical connection. One person can move some of the smaller machines.

- Cut quality: Some models cut with minimum cuts with a narrow kerf. Operators can cut many different angles easily. An angle grinder is not necessary once you use a superior plasma cutter.

- Cutting speed: Manufacturers claim that some models can complete cuts in one-fourth of the time of many other cutting tools. Also, there is minimal metal distortion.

- Portability: Small models are now produced in lightweight, portable designs suitable for one person to quickly move these machines to a variety of work sites.

- Precise cutting: Other models offer accurate cutting results producing a minimum amount of slag. They are perfect for cutting shapes and angles.

What is Pilot Arc Technology?

Late-model plasma cutters are now available with an innovation called “pilot arc.” This design reduces electrical interference with electronics situated nearby and they provide an increased stable arc while cutting. Consumables also last longer, which reduces the overall cost.

At present, they are more expensive to purchase, which offsets the savings in consumables. Machines equipped with pilot arc are great for construction sites with nearby buildings that operate computers and other electronic devices.

Tips for Using a Plasma Cutter

- Safety Gear – Use a welding helmet, proper glasses, high-quality aprons, and high topped leather boots.

- Safe Environment – Make sure the area is well ventilated and removes all flammable material from the area.

- Correctly assemble the Torch – They should be clean, consumables should be kept clean on a cloth to avoid contamination from material on the shop bench.

- Replace consumables regularly before they wear out and begin lowering the quality of your work.

- Clean the Torch regularly.

- Avoid torch collisions and do not use the Torch as a hammer.

- Proper coolant and gas flow ensures the consumables are adequately cooled and can last longer. Excess gas pressure can cause it to be challenging to start. Verify the flow every day before using.

- Maintain correct standoff from the metal to ensure the arc can flow smoothly. The incorrect standoff can damage the ideal cutting tool or the metal you are cutting. All best cutters need compressed air and ground to perform at its best.

Here is a great informative video from Eastwood Company about plasma cutting tips and tricks:

Final Words

Hope you have enjoyed our complete buyers guide and reviews on the best cheap plasma cutter on the market today. You can check price on amazon by following our links above if you need more information. We suggest purchasing the right plasma cutter with an integrated air compressor that can fit your budget options.

Last Updated on: January 11, 2023