Stick Welding Techniques for Beginners [7 Tips & Tricks]

Stick welding is a welding technique that uses an electrode and current to join a variety of metals at the weld joint. Also known as Shielded Metal Arc Welding (SMAW, stick welding) is a popular welding process.

Its versatility and simplicity have made it one of the most widely used welding processes among the major welding processes. Many people believe that stick welding got its name from the fact that you’ll need to stick the electrode to the workpiece while welding.

The electrode is also designed as’ stick,’ and it is made up of a solid metal rod at the center, which is surrounded by coating compounds and binding agents to keep everything together. However, the correct term for the ‘stick’ is the welding electrode.

The main purpose of the electrode covering is to provide arc stability and protect metals from atmospheric contaminants, so no auxiliary gas shielding is required. The composition of the electrode varies depending on the specific type of electrode.

Stick welding is used by thousands of fabricators working in heavy fabricating industries, shipyards, among other fields. That said, here are important things you need to know about stick welding if you are unfamiliar or new with the process.

Stick Welding Techniques for Beginners

1. Clean and prepare the weld area

While stick welding is one of the best methods of welding dusty or rusty metals, this should not be an excuse. You should always prepare and clean the materials prior to welding. A wire brush or a bench grinder is usually used to remove rust dirt and other debris from the area to be welded.

Overlooking this step can lead to porosity, cracking, inclusions, and lack of fusion, which can reduce your chances of delivering a good weld. So, ensure to do a proper cleaning and ensure to get a good and reliable spot for the ground clamp to ensure arc quality.

Position your connection in an area where you’ll have a good view of the weld area and where your head will be kept out of the weld fumes. Also, ensure that you’ll have a comfortable posture that will allow you to manipulate and support the welding electrode.

2. Choose current settings according to the type of welding

Stick welding settings may seem like a lot of information to master during welding, but they are vital if you want to learn the art of stick welding. One of those critical settings is the electrode current.

The electrode you’re using will determine whether your stick welder runs on AC, DC positive or DC negative. As for DC, the positive electrode offers good penetration, while the negative electrode works better on thinner metals.

So, ensure to select the correct current based on your application and always follow the manufacturer’s recommendation. Your amperage setting is also going to depend on the type and diameter of the electrode you choose.

Ideally, the manufacturer will indicate the operating ranges on the packaging, but generally, most welders offer 1 amp for every 001-inch of electrode diameter. If you set the amperage too low, the electrode might be so “sticky,” which might pose a challenge when maintaining the correct arc length.

On the other hand, if the amperage is set too high, the weld puddle may become excessively watery/fluid, which might be hard to control. Too much heat might also negatively affect the flux properties and may also produce more noise than usual.

Pro Tip: Top plasma cutting machine list if you need to cut sheet metal.

3. The welding arc length

Arc length is the distance between the puddle and the electrode. Generally, the arc length will vary depending on, type of application and the electrode. As a general rule, the length of the arc should not exceed the electrode’s diameter, i.e., the metal part of the electrode.

If the welding electrode is held close to the puddle, it decreases the welding voltage, causing the arc to go off erratically. Short arc lengths can also make the electrode stick on the sheet metal.

On the other hand, too long arc lengths may result in an undercut, and it produces more spatter, porosity, and often low deposition rates.

You may be tempted to increase the arc length to get a good view of the puddle, but it is always good to try other techniques that give you an adequate view of the pool rather than lengthen the arc.

For instance, you can choose to move your head or find a posture that you will not have trouble seeing the puddle while giving you maximum control over the electrode. So, always have a controlled arc length to ensure improved bead appearance and minimal spatter.

4. The welding angle of travel

Stick welding uses the drag/ backhand method, a technique that involves maintaining an angle of 5-15 degrees when welding in the horizontal, flat, or overhead positions.

The electrode or rod is held perpendicular to the joint and then tilted in the direction of travel at the appropriate angle. When it comes to vertical welding, the electrode is held at the same angle but tilted away from the travel course.

Always select the correct joint position as it has a huge influence on the quality of your final weld. Do your best not to exceed the recommended angle if you want to maintain your welds’ quality.

5. The speed of travel

The speed of travel should always be kept at one-third of the weld puddle. The travel speed should neither be too slow nor too fast.

If you are traveling too slowly, the heat will not be focused on the weld but into the puddle resulting in lack/poor fusion, and you also risk a burn through.

This may also result in a welding defect referred to as cold lapping (the weld appears like it is sitting on the surface, i.e., shallow penetration).

On the other hand, traveling too fast may also lead to shallow penetration with high potential for an undercut.

The faster you move the rod, the less the heat and electrode material is laid down, leading to less overall weld penetration. So, you’ll need to experiment with your metals to establish the correct travel speed for your setup.

6. Electrode manipulation

At this point, we can now talk about electrode manipulation. Every welder welds differently, so it is up to you to develop your own technique of manipulating the wet electrode for the best results.

We highly recommend that you observe experts and learn their welding styles and use them to develop yours. Some may choose to move the stick electrode from side to side to create a wide beam on thicker metals featuring a continuous series of overlapping circles.

To create even wider beams, you can make multiple passes or choose to use stringer beads. Welders can also use semi-circular and zigzag (like writing letter Z) motions to make more extensive beads, while for thinner beads, moving in a straight line may be sufficient.

7. Choosing the correct welding rods

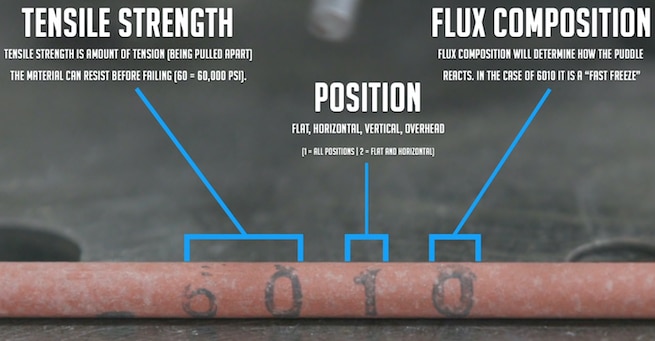

To choose the proper welding rod, you need to start by understanding how the actual electrode is numbered. Usually, the welding rods have a four-digit code from which you can identify for what kind of weld job it is capable of achieving.

Choosing the right combination of the electrode and the correct amperage is the key to a successful welding job. There are two main classifications for welding rods, and those include the 60XX and the 70XX.

In the case of the classification 60XX, the electrode is capable of resisting 60,000 PSI before failing. Basically, the first two numbers represent the tensile strength of the rod.

The second number on the sequence represents the position on which it’s best to work with. The number 1 represents that the electrode is best to use in all positions, and the number 2 represents that the rod is only good to use for flat and horizontal positions.

Last, you have the fourth number on the sequence, which represents the flux characteristics. For aluminum welding, you would need to purchase a special rod and also a welder with DC capabilities.

Other metals that would require special rods include stainless steel, bronze, and cast iron. The Everlast Welder brand has a few welding machines capable of welding on both DC and AC conditions.

Pro Tip: After you weld a car parts you need to prepare and buff the surface.

More Welding Tips For Beginners

- We strongly suggest everyone attend to welding schools to prepare themselves prior to attempting to weld themselves.

- Welding positions are crucial because you can weld at different rod angles, including flat, vertical, horizontal, and overhead.

- Choose the welding electrode wisely according to what your machine can handle.

- Look for multi-process welders that can handle Mig welding and Tig welding.

- Always use protection, including welding respirators, masks, eye protection, and welding gloves.

- Experts recommend Tig torches if you are looking for clean finished welds.

- Try to use 75% argon and 25 % carbon dioxide when welding carbon steels.

- You can achieve flat welds using low hydrogen electrodes at a drag rod angle.

- An average of 10 to 20 inches per minute is the recommended weld speed.

- Pipe welding can be achieved with multiple welding techniques.

- Try the Lincoln Electric flux-cored welding wires for outdoor applications.

- Choose a stick welding equipment that comes with a good stick electrode holder.

List of the most common type of welding

- Arc welding (Technique of arc welding)

- Mig welding

- Tig welding

- Gas welding

- Laser Welding

- Electron Beam

Whichever technique you choose, ensure to check the edges of the weld puddle to ensure that it is filling the base metal. Move slowly enough to ensure solid welds. Your deposition must be consistent in the entire area as any variations might create gaps and may increase the chances of a burn through.

Finally, you may want to grind off or just clean off your weld with a wire brush if you want a better look. Inspect your welds for uniformity and check for any signs of welding defects.

- Limitations of Stick Welding

- The process is generally considered to be manual, so it is not appropriate if you’re looking for a process that can be easily automated. This lowers the operator duty cycle, and this increases the cost of operation in the long run.

- Deposition rates are lower when compared to other welding processes.

- This process is not suitable for highly reactive metals such as zirconium, titanium.

- It is also not suitable for thinner metals as the high heat can burn through the work pieces.

- It leaves behind spatter and slag, so some clean-up is required.

Pro Tip: Here is a great post about the correct air compressor size to paint your car.

Conclusion

Stick welding is still a popular process among the arc welding methods despite being one of the earliest forms of welding. It is quite a super simple process, and it does not require complex equipment to get the job done.

The process brings in portability, and it is less sensitive to environmental factors, and it delivers excellent results in most environments. So, you can stick weld indoors, outdoors, on a production line, and similar types of location.

What’s more, stick welding is suitable for most metals and their alloys, and it is an ideal option when working in limited areas. It is also used in the auto repair and maintenance industries and the construction of heavy-duty structures as well.

In conclusion, the above tricks and tips will help you resolve any problems that beginners face when learning the art of stick welding.

Always keep practicing and be persistent in what you do, and remember every mistake is an opportunity to learn and advance your skills. And even though it is a simple form of welding, you still need to learn these skills in order to create perfect welds.

Last Updated on: October 22, 2024