HVLP vs Airless Paint Sprayers: In-Depth Expert Guide

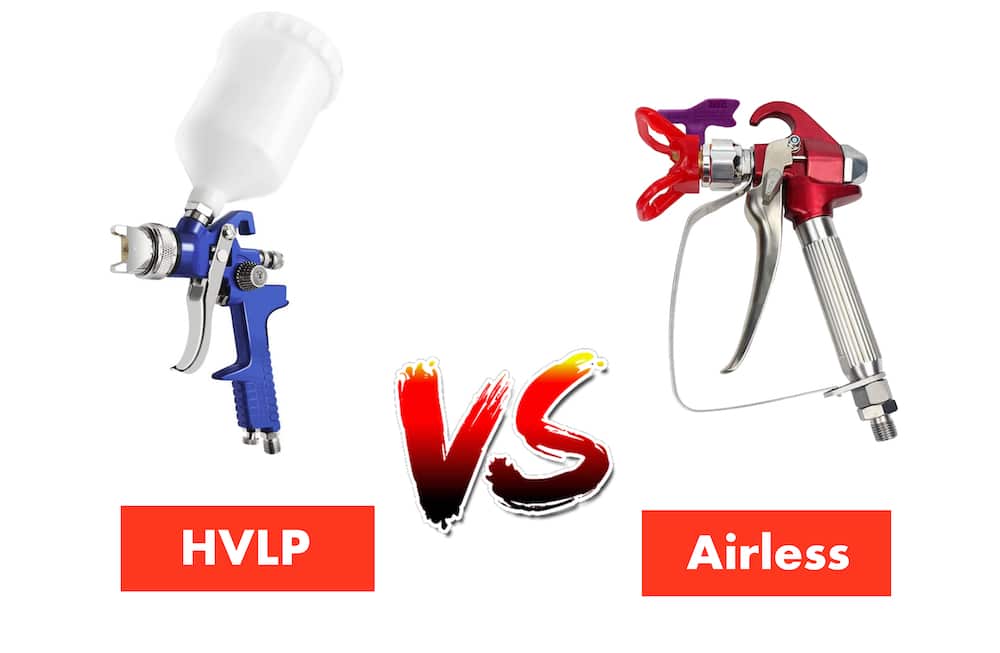

Painting is an integral part of many DIY projects. With so much to consider, deciding which type of paint sprayer is best for the job can be difficult. HVLP and airless sprayers are two popular options that offer distinct advantages and disadvantages.

In this article, we’ll explore the differences between these types of paint sprayers so you can make an informed decision when tackling your next project.

HVLP vs Airless: What makes one better than the other? How do you know if one system will work better than another? Is cost a factor in deciding which type to choose?

These are all important questions that this article will answer in detail. We’ll also discuss tips on how to get started with either system and what kind of results you should expect from each one.

By exploring both HVLP vs. Airless paint spraying systems, readers will gain insight into their respective strengths and weaknesses while discovering helpful advice on choosing the right option for their needs.

This comprehensive guide provides tangible takeaways regarding cost-effectiveness, time savings, accuracy, and more—allowing readers to confidently select the best painting solution for their projects!

HVLP (High Volume Low Pressure) Spray Systems Explained

HVLP (High Volume Low Pressure) spray systems are a type of paint application method that operates by delivering a high volume of air at a low pressure to atomize the paint or coating material. These systems are designed to minimize overspray, improve transfer efficiency, and provide a high-quality finish.

In an HVLP spray system, a turbine or an air compressor generates a large volume of air, which is then regulated to a lower pressure. The lower pressure ensures that you will have more control the paint particles are atomized into fine droplets, resulting in thicker paint, a more controlled spray pattern, and reduced bounce-back.

HVLP paint guns operate or work at lower pressure levels compared to traditional spray guns. This lower pressure setting allows for more efficient paint atomization out of the paint.

Airless Paint Sprayer Systems Explained

Airless spray systems are a type of paint application method that uses high pressure to atomize and propel the paint onto a surface.

Airless spray systems are known for their speed and productivity. The high air pressure enables faster coverage, reducing the overall application time compared to other methods.

This makes airless systems ideal for painting large areas such as walls, ceilings, fences, and exterior surfaces. Airless paint sprayer cost can vary depending on factors such as brand, quality, features, and accessories. On average, airless paint sprayers range in price from around $200 to over $1000.

Application Techniques: Airless vs. HVLP Paint Sprayers

When it comes to paint types and application techniques, Airless vs HVLP models differ in how they deliver paint onto surfaces. Understanding these differences can help you determine which system is best suited for your specific project.

HVLP Application Technique

- An HVLP paint sprayer uses a high flow of air at lower pressure not to atomize paint and propel paint onto surfaces.

- The HVLP sprayer gun releases a large volume of air along with the paint, resulting in a softer and more controlled spray pattern.

- An HVLP unit is known for its higher transfer efficiency, meaning a significant amount of paint is transferred onto the surface rather than being wasted as overspray.

- HVLP is ideal for detailed work and projects that require precision, such as furniture refinishing, automotive painting, and intricate surface coatings.

- The paint flow of the HVLP spray gun reduces the risk of paint drifting or less overspray, making them suitable for indoor applications and environments where overspray control is important.

- HVLP gun can be used to spray latex paint, but make sure to follow a specific spray tip. To spray paint, ensure the HVLP sprayer and compressor unit are ideal for spraying latex paint.

Airless Application Technique

- Airless spray systems use high hydraulic pressure to force paint through a small orifice in the airless sprayer, a gun tip, creating a fine mist of paint droplets.

- For airless units, Unlike HVLP, an airless paint sprayer does not rely on air to atomize the paint. Instead, the pressure directly forces the paint out of the gun.

- The airless sprayers tend to produce a fan-shaped spray pattern that can cover large areas quickly and efficiently.

- A airless paint sprayer allows for the application of thick coatings and materials, making them suitable for heavy-duty tasks such as painting walls, fences, and industrial surfaces.

- An airless paint sprayer is known for its speed and productivity, making them ideal for large-scale projects where time is crucial.

By understanding the differences in application techniques between airless and HVLP sprayers, you can make an informed decision based on the specific requirements of your project, the type of coating being applied, and the desired level of air control valve and efficiency.

Efficiency and Speed: HVLP and Airless Systems

Efficiency and speed are important factors to consider when comparing an Airless vs HVLP paint sprayer. Each system has advantages and considerations regarding productivity and overall efficiency of your paint job.

HVLP Efficiency and Speed

HVLP units can deliver a significant amount of paint onto the surface without excessive overspray or waste. Less paint means that you will save more money in comparison to the other traditional painting methods.

The controlled and softer spray pattern of the HVLP spraying system allows for precise application, reducing the need for touch-ups or rework.

Most HVLP sprayers are ideal for projects requiring detailed work and a high finish quality, such as automotive painting or furniture refinishing. The pattern control knob on the HVLP units are way better than those found in its airless counterpart.

Airless Efficiency and Speed

Airless spray systems excel in terms of speed and productivity, especially when covering large areas or applying thick coatings.

The high hydraulic pressure of an airless paint sprayer allows for fast and efficient application, covering surfaces quickly with fewer passes.

Airless systems are commonly used in commercial and industrial settings where speed and coverage are essential, such as painting walls, ceilings, or exterior surfaces.

When it comes to efficiency and speed, airless systems are generally more advantageous for large-scale projects where productivity is a priority.

They can cover large areas quickly and handle thicker coatings effectively. On the other hand, HVLP sprayers excel in precision and control, making them suitable for projects that require fine details and a high-quality finish.

Airless Vs. HVLP: Surface Finish And Quality Comparison

Surface finish and quality are crucial aspects to consider when comparing HVLP and other airless sprayer systems. Each system has its characteristics that can impact the final appearance and overall quality of the sprayed surface.

HVLP Surface Finish and Quality

- HVLP sprayers are known for their ability to provide a high-quality paint finish with excellent atomization of paint particles.

- The low air pressure technology of HVLP sprayers allows for a softer and more controlled spray pattern, minimizing the occurrence of overspray and providing a smooth and even coating.

- HVLP paint sprayers are ideal for applications that require a fine finish, such as automotive painting, furniture refinishing, or painting cars or intricate detailing work.

- With the HVLP paint sprayer, it is easier to thin paint to achieve a professional-looking finish with minimal texture or orange peel effect on the paint container and sprayed surface.

Airless Surface Finish and Quality

- Airless spray gun is capable of providing a high-quality finish, particularly when applied by skilled operators.

- The extreme pressure nature of airless sprayers allows for the efficient atomization of latex paint, resulting in good coverage and uniformity on the surface.

- Airless systems are commonly used for large-scale projects where speed and coverage are prioritized, such as painting walls, ceilings, or exterior surfaces.

Which Transfer Efficiency Is Better HVLP or Airless Sprayer?

transfer efficiency is an important factor to consider when comparing HVLP (High Volume Low Pressure) and airless spray systems.

Transfer efficiency refers to the percentage of paint or coating material that adheres to the surface being sprayed, as opposed to paint material being wasted as overspray or lost in the air.

HVLP Transfer Efficiency

HVLP spray guns are known for their high transfer efficiency due to their low air pressure technology and controlled spray pattern.

The type of air stream in HVLP paint guns helps to keep the paint flowing and minimize overspray and bounce-back, ensuring that a significant amount of paint reaches the target surface.

Airless Sprayer Transfer Efficiency

Airless spray guns generally have lower transfer efficiency compared to HVLP paint sprayers.

The high-pressure nature of airless systems can cause more overspray, especially when spraying at larger tip sizes or with less control over the spray pattern.

However, airless systems often deliver a much higher pressure and volume of paint per minute, allowing for faster coverage of larger areas.

Maintenance and Cleanup: HVLP vs Airless Sprayers Compared

Maintenance and cleanup are essential aspects to consider when comparing HVLP with airless sprayers.

Proper maintenance ensures the longevity of the equipment and optimal performance, while efficient cleanup saves time and resources after each spraying session. HVLP will paint thinner materials easily and with professional results.

HVLP Maintenance and Cleanup

HVLP paint sprayers, generally over airless models, have fewer components compared to airless systems, making maintenance and cleanup relatively straightforward.

Regular maintenance includes inspecting and cleaning the paint sprayer, fluid passages, and air filters to prevent clogs and ensure smooth operation.

HVLP guns often require frequent filter changes or cleanings to maintain airflow and prevent paint contamination.

Airless Maintenance and Cleanup

Airless systems have more complex components, including a high-pressure pump, paint sprayer, FFLP spray tips, filters, and hoses, which require regular maintenance to keep them in optimal condition.

Maintenance tasks for airless systems include inspecting and cleaning the pump, lubricating moving parts, checking and replacing worn seals or packings, and ensuring proper pressure settings.

Cleanup after using an airless system involves purging the system with an appropriate solvent to prevent paint from drying in the pump, gun, or hose.

HVLP vs. Airless Paint Sprayers: Cost To Adquire

HVLP Spray Gun Cost

HVLP spray systems typically have a higher upfront cost compared to air spray systems. HVLP guns require a specific turbine or compressor unit to generate the low air pressure needed for the spray gun.

These HVLP systems can range in price from around $200 to $800 or more, depending on the brand, power, and features.

Additionally, HVLP spray guns themselves can range from $50 to $500, depending on the quality, brand, and additional features like adjustable controls or different HVLP nozzle sizes.

Airless Paint Sprayers Cost

On the other hand, air spray systems generally have a lower upfront cost. Air spray guns are typically less expensive, with prices ranging from $30 to $200, depending on the brand and quality.

Air compressors used with air spray guns can range in price from $100 to $500 or more, depending on the size, power, and features. HVLP uses air pumped from an air compressor to atomize paint and have more control during the paint job.

Tips For Choosing the Right Paint Sprayer: Airless or HVLP Sprayer

Ultimately, the best choice depends on your specific requirements and preferences. It may be beneficial to consult with professionals or industry experts who can provide guidance based on your specific application needs.

Professional painters would typically use a paint sprayer that produces minimal overspray and more even coats when dealing with interior project. The HVLP sprayer is ideal for these projects that require low to medium viscosity coatings.

Some of the paints that an HVLP sprayer can process include the following:

- Siphon paint

- Oil based paint

- Unthinned paint

Regardless of the system chosen, proper maintenance, technique, and adherence to safety guidelines are essential for achieving optimal results.

Last Updated on: October 22, 2024