What Air Pressure for HVLP Spray Gun? (Ultimate Guide 2023)

Have you ever found yourself staring at an HVLP spray gun, wondering what air pressure to use? It’s a common predicament for both beginners and experienced painters alike.

The air pressure you choose can significantly impact the quality of your paint job, affecting everything from the finish to the amount of overspray. But fear not!

So, what air pressure for HVLP spray gun should you use? In this guide, we’ll explore the world of HVLP spray guns and the optimal air pressure settings to help you achieve outstanding results.

A constant air pressure can be created by adding a regulator. However, you cannot restrict air flow too much because it can create excessive pressure drop on that initial burst.

Whether you’re a DIY enthusiast or a professional painter, understanding the right air pressure for your HVLP spray gun is crucial for unleashing your painting potential and optimum performance. So, let’s dive in and unlock the secrets behind the perfect air gun pressure for HVLP guns.

Why Maintaining Air Pressure Matters?

Air pressure is important because it determines how HVLP paint sprayers push the paint through the system and out of the nozzle. The paint is turned into tiny droplets before it is sprayed.

Whether you choose a conventional air spray with a compressor or a built-in turbine, most machines have a dial that lets you adjust the air pressure easily. Most HVLP sprayers atomize different coatings by utilizing a high volume of air at low air cap pressure.

Paint spraying with an HVLP sprayer requires compressed air in order to operate efficiently. If pressure decreases, the spray paint pattern can become inconsistent. Therefore, it is important to ensure that the air pressure is properly adjusted and maintained while using an HVLP sprayer for paint spraying.

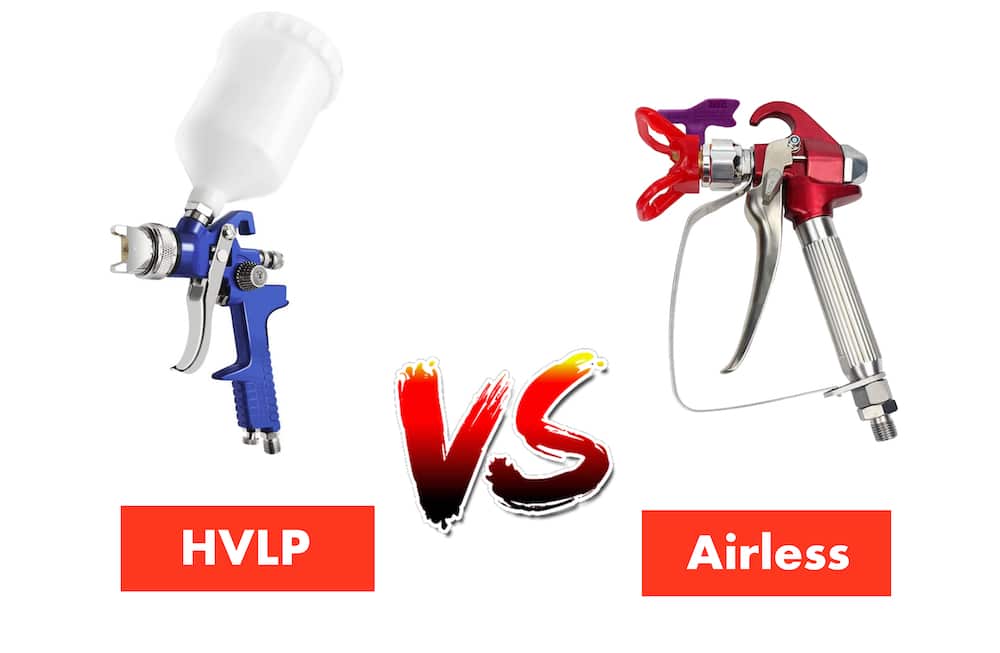

HVLP vs. Airless Pressure

HVLP stands for high-volume, low-pressure. The sweet spot for an HVLP paint sprayer is around 15 to 26 cubic feet per minute (cfm) of air from the turbine. This amount of air creates about 10 pounds per square inch (psi) of pressure.

It’s a relatively low pressure, which reduces the amount of paint that bounces back. HVLP units work well for small to medium-sized projects in tight spaces. However, using the above pressure will take a long time if you need to cover a large area.

This is where airless systems come in handy. Airless paint sprayers operate at a much higher air pressure, between 1500 to 3300 psi. This allows them to finish big projects quickly, but they tend to produce more overspray.

Using an air filter can reduce the amount of PSI and changes the system pressure. Most experts tend to add the air filter prior to modifying the adjusted pressure. Try playing with the air volume knob that is located at the bottom of the sprayer if you need less air to go thru it.

Pressure and Nozzle Sizes

Usually, the size of the nozzle depends on the type of coating you’re using. For instance, if you want to use thick paint like heavy-bodied latex, you’ll need a nozzle with a small opening, around 0.021 to 0.025 inches. But for an oil-based enamel, a nozzle with a slightly larger opening, between 0.013 and 0.015 inches, will do.

So, how does this relate to the air pressure setting of air spray guns? If you need to spray a thick coating through a wider nozzle, you’ll need higher pressure. On the other hand, if you’re using a thin coating with a narrow nozzle, lower pressure will be enough.

Not all sprayers are the same, so make sure your unit can handle thicker materials. For example, the Earlex 6003 is suitable for dense coatings and has the right size nozzle.

Pneumatic HVLP Spray Guns

With pneumatic sprayers that use an external turbine, you have many options when it comes to adjusting the pressure settings.

If you need a spray gun for automotive refinishing, applying base coats, or general tasks, the Iwata WS400 Supernova Compliant Evotech is considered one of the best in the industry. It requires 12.57 cfm and atomizes paint at an impressive 29 pounds per square inch (psi).

On the other hand, if you don’t need such high specifications and plan to spray stains or apply finishing touches, the Central Pneumatic Touch Up spray gun might be suitable for you. Both of these paint guns have a small dial on the side to adjust the pressure.

Inline Pressure Gauges

Determining the correct pressure output for this sprayer can sometimes involve trial and error, as you’ll see in the next section. However, using an inline pressure gauge lets you note the ideal pressure setting.

This way, your spray gun will be ready the next time you use it or after a short break during a project. Many sprayers, including the Goplus Air HVLP spray gun set, come with an inline pressure gauge included. If you find a spray gun that you like but doesn’t have a gauge, you can always buy one separately.

DIY Application for Air Compressors

When it comes to small-scale DIY applications, selecting the right air compressor for your sprayer is crucial. A 20–35-gallon (75-133 liter) air tank and a compressor that delivers 1.5-2.0 horsepower under load can provide an ideal setup for small shops or home garages.

If your painting projects primarily involve smaller vehicles such as cars or motorcycles, using this type of air tank with an LVLP spray gun is a suitable option. LVLP guns, with their lower air consumption, can effectively operate with the air supply provided by these small compressors.

However, it is important to be aware of the issue of condensation that can occur in air compressors, regardless of their size. To mitigate this concern, it is recommended to incorporate two water filters within your setup. One filter should be positioned approximately 10-15 feet away from the tank to remove moisture from the air before it reaches the sprayer.

Additionally, another filter should be installed at the gun neck to prevent water from entering the sprayer. These inexpensive plastic water filters, typically priced around $5, are threaded onto the air inlet of your sprayer and effectively keep your lines free from water contamination.

It is essential to consider the power requirements when using a small compressor. Typically, a small compressor will be powered by a 110-volt outlet. It is important to note that the maximum horsepower a 110-volt line can safely handle without tripping the breaker is approximately 2 HP.

Therefore, when selecting a small compressor, ensure it falls within this power limit to maintain a stable power supply without interruptions.

By carefully considering these factors and selecting the appropriate equipment for your small-scale DIY applications, you can set up a reliable and efficient air compressor system that meets your painting needs while maintaining optimal performance and quality.

Factors That Impact HVLP Air Pressure

Three factors can affect the air pressure requirements for air spray guns: cold weather, the use of thinner, and the length of the air hose. When it’s cold outside, liquids tend to become thicker.

Thicker liquids are more difficult to atomize effectively. You may need to increase the air cap pressure slightly to compensate for the temperature variation. A helpful tip is to bring your fluid, stain, or other finishing medium indoors and let it reach room temperature before spraying.

Thinning is often necessary for many fluids before using a paint sprayer. Thinning helps the spray medium flow smoothly through the gun. The manufacturer’s recommendation on the fluid can is usually for unthinned paint. If you have added thinner to your paint, be prepared to change it to low pressure to achieve the best results.

The length of your air hose also plays a role in air pressure. As air travels through the air hose from the compressor to the spray gun, some pressure is lost along the way. The longer the air hose, the more significant the pressure loss becomes.

If you’re using an extremely long hose, it’s advisable not to excessively crank up the air pressure. Instead, consider using a high-flow air regulator that can be attached to the end of the hose where the spray gun is connected. You can prevent any pressure drop by adjusting the pressure right before the air enters the gun. This allows you to fine-tune the pressure without having to stop spraying.

Frequently Asked Questions

Q: What PSI should I run my HVLP spray gun?

A: The optimal operating pressure for these sprayers typically ranges between 20 to 30 pounds per square inch (psi). However, it’s important to refer to the manufacturer’s guidelines or instructions for your specific HVLP gun model to determine the recommended pressure range.

Q: What is the maximum pressure for HVLP?

A: Most HVLP spray guns are designed to operate at lower pressures compared to conventional sprayers. The maximum pressure for HVLP guns is usually around 10 psi. Exceeding this pressure can affect the spray pattern, atomization, and overall performance of the HVLP system.

Clean your sprayer before applying clear coats so that there is enough air pressure for the application. Also, clean the quick disconnect fittings, hose, and filter of your HVLP gun. That way, you can ensure a high transfer efficiency when spraying the fluid.

Q: What pressure should I set on my spray gun?

A: The pressure setting for your spray gun depends on various factors such as the type of coating, viscosity of the material, nozzle size, and specific spray gun model. What size air compressor to get? A larger compressor is needed for some professional sprayers, and that depends on the volume requirements of the unit.

It’s recommended to start with the manufacturer’s suggested pressure range as a starting point and make adjustments based on the desired spray pattern and application requirements. Conducting test sprays on a scrap surface can help you determine the ideal pressure setting for your specific project.

Last Updated on: July 6, 2023