How Does a Turbocharger Waste Gate Works? [5 Turbo Tips]

The wastegate is a turbocharger’s very important device, which makes sure the motor will not get much boost pressure as its turbo revs and spools build.

So, how does a turbocharger waste gate works? A wastegate can be defined as a flap or gate that opens in order to divert any excess pressure from its turbo into either the atmosphere or the exhaust instead of doing it into the turbo.

By doing so, a wastegate will protect and regulate the turbocharger and engine from any excess boost. The wastegate will open and divert any pressure away from a turbine wheel when any boost pressure reaches certain points such as 10 psi.

What Does a Turbo Wastegate do?

The job that a wastegate needs to achieve is to allow the exhaust gases to bypass the turbine. This will help to control the speed of the turbine and prevents the turbine wheel from over spinning.

By controlling and limiting the turbine’s wheel speed, the wastegate regulates the boost pressure. The wastegate protects the turbocharger and the engine from damage by preventing the boost pressure from rising too much.

How Does The Wastegate work?

A turbo wastegate is usually held by a spring in the inside of the actuator. Whenever the boosting pressure overtakes the maximum threshold that is set by the manufacturer, it proceeds to compress the spring.

Afterward, the compression allows the wastegate to open progressively, allowing the exhaust gases through. These exhaust gases bypass the turbine, and then it starts to regulate the speed.

Different Types Of Turbocharger Waste gates

You can find two types of wastegates in the market: internal wastegates and external wastegates.

Internal Wastegate

The internal wastegate tends to be found on vehicles with low boost settings such as 6 psi or 5 psi. This type of wastegate is very important for the turbo itself and you can find it inside any turbine housing. This type of system comes with an integrated wastegate valve that is attached to the turbine housing.

A hose is connected to the diaphragm that goes directly to the intake manifold, charge pipes or compressor outlet. When this diaphragm is activated, the gate will open. A wastegate flap will be opened in order to slow down the boost pressure by using the turbo`s impeller.

If the boost pressure exceeds it will be evacuated to the machine’s exhaust. It serves as a bridge that lets the exhaust gas through, allowing them to bypass the turbine and then regulates the speed.

External Wastegate

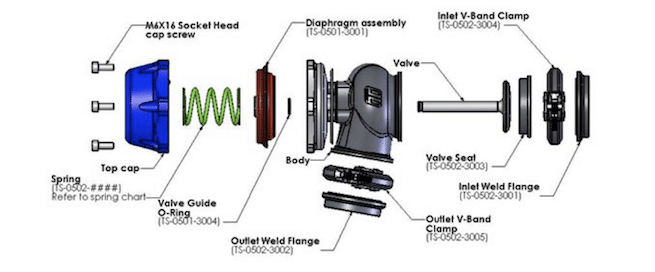

The external wastegates can be found separated from its turbine housing and it does not require any mechanism to work. A valve, which can be similar to that of a cylinder head, is used to activate this sort of wastegate.

Any excess exhaust gases will be either evacuated into the outside atmosphere or diverted from its turbo to the exhaust. The former is really much louder than the latter.

Setups generating from twenty psi to thirty psi will work fine with an external wastegate, and most turbo kits tend to use an external wastegate too. You have to use a special exhaust manifold in order to install this type of wastegate, which will use an extra runner designed for this type of wastegate only.

External wastegates tend to regulate the level of boost with more precision than internal wastegates due to the fact that the former does not come with space restrictions. A key feature is that they come with high intake manifold pressure springs to achieve a high boost pressure.

Tips For Testing a Turbocharger Waste Gate

Remember that a turbocharger is just an air compressor that is driven by any exhaust gas out there. These are some tips to test your turbocharge wastegate so that it does not over-speed.

If your compressor does not have an adjustable pressure regulator, install one into the quick-disconnect fitting of the air-line. Then adjust your regulator in order to cut some pressure at the maximum psi levels of your turbo.

You can find the right boost level online or in a repair manual if your car does not come with a boost gauge in the cabin. Get rid of the boost sensor line of your wastegate from either the intake manifold or the intake tube, but it will be dependent on the type of engine.

Although types and locations tend to vary, the boost sensor line commonly comes attached to the wastegate on any turbo out there. Disconnect your line after following this line from its wastegate to the intake.

To build more boost pressure, turn on the compressor and install your air sprayer into your air line`s end. Press the rubber tip of the sprayer into the boost line`s end after your compressor turns off. The wastegate`s actuator rod should move when applying the compressed air after hitting the sprayer`s trigger.

If you do not have an external actuator rod in the wastegate, you must listen for some sounds. The stethoscope might help you hear something when the compressor and engine are off, and you should be able to do it without any assistance.

Use a long screwdriver and press its tips to the turbo`s base in case you do not have any medical supply. Grasp the screwdriver handle and put your ear on it in order to hear the sound of the metal shaft of the driver. Re-test your regulator after turning its setting down by around 2 psi.

The wastegate spring is worn out if the wastegate opens early. You will get less horsepower if your valve opens at 4 psi or even lower, which will happen if your wastegate spring is really worn out. However, any movement of 2 psi really below max is quite normal.

Misconceptions to Consider About Wastegates

A turbocharger would increase the horsepowers to your vehicle as long as you can keep it under control. It is not doubted that your car’s performance will improve, but there are some common misconceptions when it comes to a turbocharger wastegate.

In theory, you could probably add a turbo to your vehicle without the need to install a wastegate. However, this would not be the best scenario for your engine. If your mechanic makes the mistake of adding a turbo system that exceeds the maximum boost pressure, your engine can blow up.

Summary

Turbocharged engines are super fun to drive. The wastegate device bypasses the exhaust flow to archive higher boost levels when shifting gears. You will notice a special sound that comes from these type of engines. Also, the engineers per-select the wastegate actuator to achieve the desire boost levels on a specific model.

Understanding the different functionalities of these devices is our passion. We provide you with the best information there is. Also, we appreciate the time for visiting our website. You now know the difference between internal wastegates and external wastegates, and how they control the exhaust gases. For more information go to our engine blog.

Last Updated on: February 21, 2024