Top 27 Reasons Why Your Car Engine Cranks But Wont Start

If your car engine does crank but won’t start, the battery, cables and starter motor are not the cause. Typically, in this situation, the causes of car engine failure can be no spark, no fuel, or potentially a leaking valve.

Drivers should avoid cranking the engine repeatedly or continuously. So, what are the reasons why your car engine cranks but wont start?

The battery could be depleted, or the starter could overheat and be damaged. Other components in your starting system could also be damaged. Regular car maintenance can prevent many of these problems, and you should not experience a crank but not start situation.

27 Reasons Why Your Car Engine Cranks But Wont Start

A car that cranks but the car won’t start can have many potential reasons for not starting.

1. Check engine light

The check engine light illuminates whenever the Engine Control Module detects a problem with a component of the fuel system, the ignition system, and many other components. The light does not indicate which part or component.

A code reader must be attached to the ECM to read the code or codes that have been generated. This code indicates the trouble codes and directs the auto repair mechanic to the areas that may be causing the problems. If your car doesn’t start, this could be an excellent first place to start.

2. Bad fuel pump relay

A fuel pump relay controls the power to the fuel pump. If this relay is not working correctly, the fuel pump cannot deliver fuel to the engine. This can cause an engine that cranks but doesn’t start without fuel regardless of the amount of cranking.

Listen for a low volume hum from outside the vehicle near the fuel tank with the ignition switched on. If it is not working, fuel is not getting to the engine, and the engine starts and stalls or cannot start.

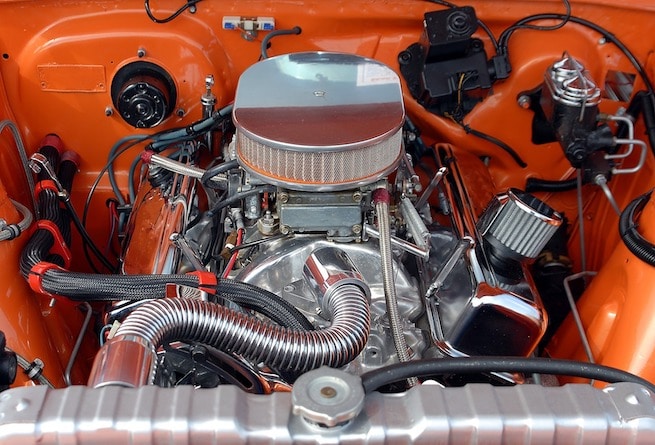

3. Spark plug wires

Spark plug wires can degrade over time, developing cracks and even open connections as they age. If your plug wires have not been replaced in three or four years, verify their integrity and change them if needed. Spark plugs should also be inspected, cleaned, and re-gapped or replaced.

If they are dirty or badly corroded, replaced them with new plugs. Make sure that the proper gap is applied to maximize the spark. Also, inspect your distributor cap in older cars for corrosion or cracking. The distributor cap could also be a source of problems that cause spark plugs that won’t fire.

4. Blown head gasket

Engines with a blown head gasket may exhibit the following signs: coolant leaking from below the exhaust manifold, white smoke from the exhaust, low coolant level, engine overheating, low power from the engine, and white milky looking oil.

Running an engine with a blown head gasket can damage the engine further leading to thousands of dollars in repairs. A blown head gasket usually means there is low compression in one or more of the cylinders. Arrange for immediate repairs to the engine with a new head gasket.

5. Bad ignition switch

The ignition switch causes electrical power to be sent to a variety of circuits in your car, including the fuel pump, the engine control module, and many others. When you turn the key in the ignition of the car or press the start button, the engine should crank and start.

Symptoms of bad ignition switch include the engine failing to crank and not start, stalling or switching off on its own, and any number of electrical problems.

6. Blown fuse

Another easy trouble shooting step to take is to confirm that the fuses have not blown. Fuses that control the fuel injection system, the engine computer system, and other components can prevent the car from starting.

The fuse block is usually located under the hood, however, check your cars owner’s repair manual for the exact location for your vehicle and additional repair advice.

7. Bad starter motor

Starter motors engage immediately with the car crankshaft when they are operating correctly. Failing to crank, or unusual noises when the starter motor engages indicates that the starter motor is not engaging successfully.

A slow cranking of the starter motor can indicate a poor connection to the battery or the starter motor. Always check the battery connections to ensure that they are solidly connected. Verify that there is not a broken cable.

8. Batteries of the ignition key

Late-model cars rely on electronic keys that provide increased security for the vehicle. Even though you still insert the key in the ignition, if the battery in the ignition key is dead or low, the system may prevent the car from even cranking.

Many vehicles use a FOB which is kept in your pocket or purse. A dead battery in the FOB also prevents the car from starting. The engine will not even crank.

9. Coolant temperature sensor

The engine control module relies on the engine coolant temperature sensor to monitor the temperature of the coolant of the engine. If it is not working correctly or reporting high temperatures, the ECM turns on the check engine light on your dash.

Car owners should have this checked by reading the error code saved in the ECM using a code reader. A bad coolant temperature sensor can cause your engine to overheat or the engine to run roughly. Have your engine checked before damage from overheating occurs.

10. Bad fuel filter

A bad fuel filter can occur when the filter becomes clogged and limits the amount of fuel delivered to the engine even though the fuel pump is operating correctly. Lack of power when accelerating often occurs because insufficient fuel is getting to the fuel injectors.

The engine may also stall or even misfire. Fuel filters can become clogged due to draining a gas tank very low. Impurities settle to the bottom of the tank as cars age and are drawn into the fuel line when the fuel is very low in the tank.

11. Timing belt or chain

The crankshaft drives the timing belt or timing chain. It drives the camshafts which control the intake and exhaust valves delivering air and fuel to the engine and then exhaust after combustion respectively. A bad timing belt or chain can cause severe engine mechanical damage.

Worn timing belts or chains may open or close the valves at the wrong time causing poor combustion and even damage to the engine. If you hear a noise inside the motor engine or vibration inside the engine, this may indicate a bad or failing timing belt or chain.

12. Broken battery cable

A broken battery cable or one that is almost broken due to fraying often means that your starter cannot operate at all. Dash lights do not work, and your car is dead. If the cable is broken, even a boost from another car cannot do the job.

Always check that the battery cables are tightly connected to the battery terminals and that the cable is securely attached to the starter motor. Cold weather can also affect the battery, depleting an older battery quickly.

13. Bad mass air flow sensor

The mass air flow sensor measures the amount of air entering the engine, and the engine control module controls the amount of fuel added to the air to control the engine speed. If the mass airflow sensor fails due to corrosion, dirt, and contaminants, the ECM may turn on the check engine light.

The ECM also saves an error code which can be read by a code reader. Symptoms include failure to start, a poorly running engine and even shifting problems in an automatic transmission.

14. Safety switch on

The neutral safety switch only allows you to start the engine when the automatic transmission is in park or neutral. The safety switch prevents the car from being started while in gear.

Without the safety switch, the vehicle might launch forward if the automobile was started while in gear. A car that won’t start or even crank the engine might have a bad safety switch.

15. Crankshaft position sensor

The crankshaft position sensor is found in all modern combustion engines. The crank sensor monitors the crank position of the crankshaft and also the rotational speed of the crankshaft.

Also, the engine control module uses this information to manage the air intake, the fuel needed to run the engine and control the fuel injection system to deliver the fuel-air mixture at the right time to maximize efficiency and power.

You an expect the check engine light to be illuminated if there is a problem with the crankshaft sensors.

16. Bad ignition coil

Ignition coils take the battery’s 12 volts and convert it to thousands of volts needed to generate the spark at the spark plug. Most cars have one coil per sparkplug; however, some older cars have a single coil connected to all of the spark plugs.

A bad ignition coil may cause the engine to misfire, run rough, and also lose power. The check engine light may also turn on signaling that an error code has been generated.

Also, check the wires for fraying and damage. If the coil is bad, you can have a situation where the car cranks but won’t fire and start the engine.

17. Fuel pressure regulator

The fuel pressure regular maintains the desired fuel pressure in the fuel system to ensure that adequate fuel is delivered to the engine to meet desired power requirements.

A faulty fuel pressure regulator can cause a decrease in power and acceleration, possible fuel leaks, which is a safety hazard. A failed regulator can also cause black smoke to be issued from the tailpipe due to a high air-fuel mixture.

18. Step on the clutch pedal

Failing to step on the clutch pedal while trying to start the engine prevents the engine from starting. There is a sensor switch that determines the position of the clutch and tells the engine control module, whether it is safe to start and run the car or not.

The engine won’t crank in this situation. Starting the car with the clutch not depressed and the vehicle in gear would cause the car to lurch forward, causing a potential safety hazard.

19. Bad intake manifold gasket

A bad intake manifold gasket is usually caused by corrosion of the gasket which is made of paper, rubber or metal or a combination of all three. Symptoms include backfiring, hesitation, low power, hard to start, poor fuel economy, rough idle, stalling, and more.

The check engine warning light may also be turned on providing additional information. Since these symptoms are also potential symptoms of other problems, it can be challenging to diagnose a manifold gasket problem.

Mechanics may use a smoke machine while the engine is running to see if the air is being drawn into the manifold along the gasket.

20. Antitheft system on

The antitheft system that came with your car or installed aftermarket may have developed an error condition if the battery in the chip in your key has failed. Test and replace the battery.

If it still is not engaging with the car, consult the manual for the antitheft system or call the auto shop that installed the alarm system. There are often step by step procedures to correct errors and to check if the system is malfunctioning.

21. Clogged or spark fuel injectors

A clogged or bad fuel injector is challenging to diagnose. One or more cylinders is not firing and producing power. It could be a bad injector, a clogged injector, a bad coil or a bad spark plug wire.

One way to figure out which one is not working is to feel the manifold at each injector. If it is not firing, the manifold is cooling at that site. Be careful if your engine is hot. Use droplets of water instead. Next, you have to figure out if it is the injector or the coil pack.

22. Bad ignition module

The ignition module controls the spark delivered to the sparkplug. A bad ignition module can cause engine performance problems such as misfires, hesitation, and loss of power. The engine may also stall, and it may be difficult to restart the engine.

You find problems with the ignition if the ECR cannot control the proper amount of spark and fuel without accurate information from the sensors.

The engine control module may illuminate the check engine light and store an error code. Which can be read with a code reader to provide additional information about what is not working correctly.

23. Vacuum Leaks

Vacuum leaks can cause poor fuel efficiency, a loss of power, and even damage the engine. Your car may idle very fast, and it also may stall, which can be symptoms of other problems with sensors. Open the hood and listen for a loud hissing noise.

This is a telltale symptom of a vacuum leak. Depending on the location, you may need to have a mechanic replace the part. Check first to determine if a clamp is broken or needs to be better secured. You may need a test light to observe the area.

24. Failing throttle body

The throttle body provides information about the desired speed to the engine control module to assist in delivering the correct amount of fuel to the engine.

Symptoms of a failing throttle body are engine lacks power, slow or poor acceleration, the engine may not idle smoothly or even stalls, the car may accelerate up to a low speed, the automatic transmission may not shift up, and the check engine light may come on.

25. Throttle position sensor

The throttle position sensor continually measures the position of the throttle to determine the desired speed and power required of the engine. A failing throttle position sensor can also cause poor fuel economy and poor power management when you accelerate.

The engine control module takes this information and combines data from this sensor, the air mass sensor, the fuel sensor and current speed of the motor engine to assess how much fuel should be added to the air intake to provide the desired engine power.

26. Manifold absolute pressure sensor

The manifold absolute pressure sensor measures the air flow intake and provides this information to the engine control module, which calculates the correct amount of fuel to add to deliver the desired power. The sensor may become clogged, or the vacuum lines are broken. Even the engines heat can sometimes wreck the electronics of the sensor.

A bad sensor may cause poor fuel economy, lack of power, and your car can fail an emissions test. The engine may have a rough idle, it may be hard to start, and it may even stall. The check engine light may illuminate, and an error code may be saved in the ECM. Use a code reader to check the error code.

27. Cracked car battery terminals

Cracked car battery terminals, corroded terminals, loose connections can all lead to a lower voltage and current delivered to the starter motor. If the battery cables are broken or not making a connection with the battery terminals, the engine may not crank at all.

Operators may hear a clicking noise and the lights come on. There is not sufficient power getting to the starter motor to crank the engine. Getting engines to start in these situations is difficult.

Other reasons why your car engine not starting

A common cause that most people ignore when a car engine is not starting is to check the fuel levels. An empty tank will be the most common cause why a vehicles motor won’t start.

Also, some cars have a security system that will automatically block the engine from starting if you forget to do little things like not stepping on the brakes. Read the owners manual to find out precisely what your car’s minimum requirements are to avoid for the security system to prevent your automobile from starting.

Car repair and troubleshooting have become more comfortable for an average person. Most code readers available on the market can let you know if the car has a bad map sensor, camshaft position sensors, low starting fluid, or any of the previous mention reasons why your car cranks but won’t start. Also, this makes it easier for mechanics to fix an engine problem much faster.

All the above mentioned is a common cause why a car produces a grinding noise when you try to start it. Sometimes it is just a simple adjustment like filling up an empty tank, and other times it can get more complicated like for example, your car needs a new coil pack, or there is a problem in the electrical system.

Also, most of these problems are typical for cars like Nissan Rogue, Honda Accord, Honda Pilot, Honda Fits, and any Ford vehicle.

What To Check When Your Engine Cranks And Refuses To Start

Your vehicle’s engine may refuse to operate as expected for several reasons. The culprit is always related to the three things your engine needs most: fuel for combustion, sufficient compression within the cylinders, and a spark. Without all three, the engine will not perform as it was designed. The problem is, each can be affected by other parts and systems, making it difficult to diagnose the root cause of a problem.

In this article, we’ll focus primarily on the factors that can cause your engine to crank (i.e., turn over), but not start. We’ll begin with the items that are easiest to troubleshoot and advance to the more complicated things toward the end.

Inspect The Fuses First

This step sounds intuitive, but a lot of people neglect to do it. Whenever you’re experiencing issues with components that rely on your vehicle’s electronics, check the fuses before anything else.

The reason cars have fuses is to protect the electrical circuits from overload. If a particular fuse burns out, the part or assembly controlled by it will stop working. This includes your engine and components that influence its operation.

Look in your owner’s manual to find out which fuses affect your engine. Then, open the main panel, remove the fuses, and inspect them. If the links inside are broken, the fuses are bad. If the links are intact, they are excellent.

Pull The Trouble Codes

When your engine experiences any deviation from its average performance, it will produce an OBD-II trouble code. This code is logged into your car’s computer.

This allows a mechanic to retrieve it and have a better idea regarding where to start looking for the root cause of the deviation. If you have an OBD-II scanner, you can pull it yourself. You can purchase a scanner at many auto supply shops for less than $40.

Pulling codes from the computer is easy. A diagnostic connector is usually located in your vehicle’s cabin underneath the dashboard. You can plug the scanner into this connector to pull the codes from the computer.

These OBD-II codes are alphanumeric (e.g., P1086, P1822, etc.). Once you have pulled them, look for their definitions online. This may provide helpful clues regarding why your engine refuses to start.

Examine And Test The Engine Spark Plugs

Recall that one of the three things your engine needs is a spark. Hence, each cylinder has a spark plug (sometimes, two) that ignites the compressed air-fuel mixture within each cylinder’s combustion chamber. This results in a mini-explosion within the chamber. The explosion produces vapors that expand rapidly and push the piston downward, which turns the crankshaft.

Unfortunately, spark plugs become fouled over time. Deposits can accumulate on them and make it challenging to generate a sufficient spark. Also, this can cause your engine to crank, but refuse to start correctly. If the spark plugs appear excellent, it’s time to test the pressure within the assembly.

Check The Combustion Chamber’s Compression

For the air-fuel mixture to ignite within the cylinder, it must be sufficiently compressed. Also, this means the cylinder should be free of severe compression leaks. Often, the exhaust valve will fail to close correctly, and thus allow air to escape during the combustion process. If a leak is severe, it can prevent your motor from starting.

You can purchase a compression gauge for less than $40. If the compression within the cylinders is excellent, you’ll need to test your ignition system.

Is Your Ignition System Operating Properly?

Several components comprise your ignition system, and a failure that affects any of them can impair your engine’s performance. These include the spark plugs, distributor and distributor cap, rotor, ignition coil, and other pieces. Unless you’re experienced with automotive diagnostics, it’s a good idea to have a mechanic test these parts.

If your engine cranks, but will not start, follow the troubleshooting guide above. If you can isolate the problem to the fuses or spark plugs, you’ll be able to resolve it on your own efficiently. Selling the car off is not always a good idea, but getting the engine fixed is a much better and cheaper option.

If the engine has worn out due to the excessive usage, it may require to be rebuilt to increase its durability and boost up the performance. Or it may need reconditioning for more exceptional looks and smoother operations.

There are some professionals, highly trained in reconditioning of engines, which make it so soft that you wonder if that was the same engine you had given to them. Bear in mind one thing though, engine reconditioning, every so often, does not work out as anticipated.

Should i Consider an Engine Replacement?

Nevertheless, if you love your car so much and willing to keep it for long, the better is to opt for an engine replacement rather than engine reconditioning. The question may arise why not go for a reconditioned engine? Why go for a replacement engine anyway?

The answer to all these questions is that in reconditioning the engine, plenty of efforts are put in to give it an excellent finish and make it look like a new one whereas fewer parts are replaced or reworked to provide the engine with a longer life and better performance. It comes with the satisfaction of the owner for all the money paid.

On the other hand, when opting for an engine replacement, the whole engine is rebuilt and reworked for optimal performance and even longer life with a smoother ride. The cylinder head and the engine block is worked to match the adjustments of the polished and machined crankshaft.

Appropriate oil pressure is maintained by the installation of bearing sets and flat mats in leading journals and connecting rods. After fitting the new pistons, the cylinder head and chambers are pressure tested for internal cracks, thus creating a positive seal.

The last thing done is the installation of new oil seals to ensure they keep the pressure up and are tight enough to hold the oil in.

Final Thoughts

Hopefully, this article can help you identify the reasons why your car won’t start. These causes are common in both gasoline engines and diesel engines. Before going to a car repair center, check the fuel levels, car battery, and the owners manual to see if you can identify the problem yourself.

After a few failing attempts if you hear the engine crank but won’t, you can try calling a local car care center for repair advice. Other problems in the electrical system, bad map sensor, crankshaft sensors can cause the engine to crank or make a grinding noise when starting.

Last Updated on: July 13, 2022